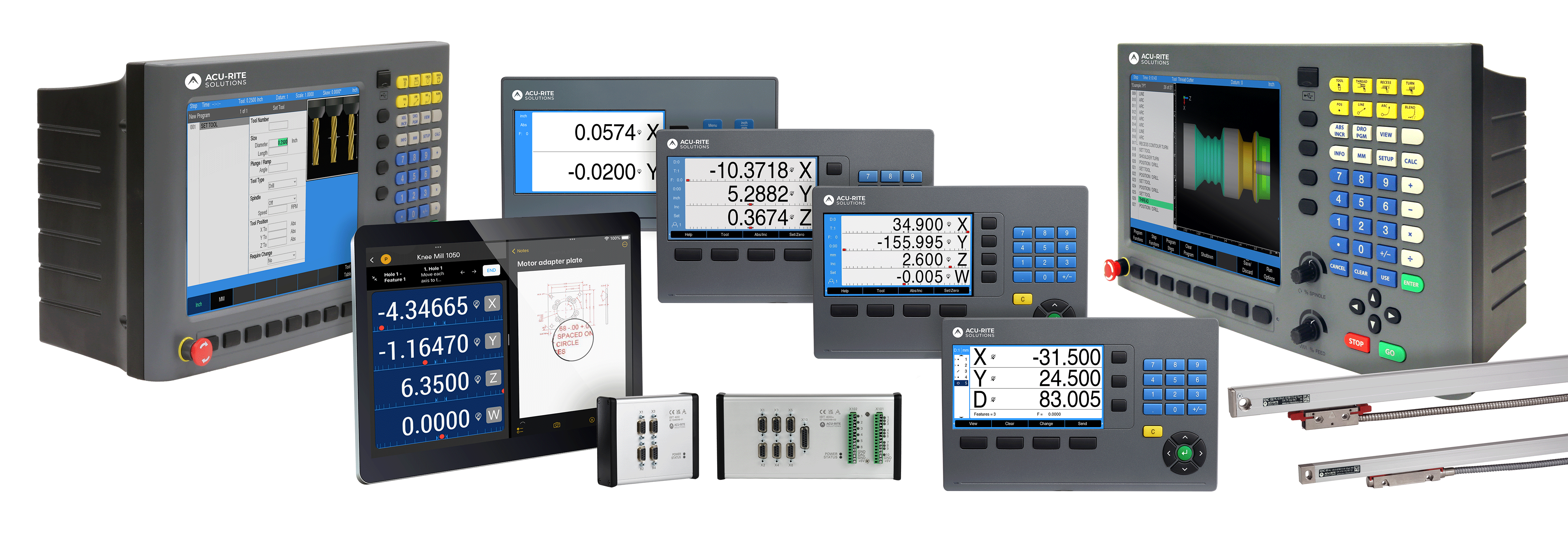

Acu-Rite Solutions creates precision CNC control and digital readout (DRO) systems compatible with an extensive range of machine tools. Whether you are looking to buy a new machine tool or already have one, integrating Acu-Rite Solutions technologies is a cost-effective way to improve its accuracy and efficiency. Keep reading to explore the compatibility of Acu-Rite Solutions technologies and how they will benefit your manual machining.

Custom Bracket Kits for 100+ Machine Makes and Models

Acu-Rite Solutions CNC control and DRO systems are for milling, turning, grinding, boring, EDM, and large machine tool applications. We offer custom bracket kits for different mounting positions on over 100 specific machine tool makes and models.

“Our custom bracket kits simplify installation because they eliminate the need for bracket modification,” said John Parker, product manager at HEIDENHAIN CORPORATION. “They set Acu-Rite Solutions apart from other brands, which either don’t provide brackets or offer brackets that must be modified to fit the machine.”

Custom bracket kits from Acu-Rite Solutions come with a step-by-step installation guide to maximize machine tool uptime. This means you can seamlessly integrate Acu-Rite Solutions CNC control and DRO systems into new or existing machines:

- New Installations: Choose the machine tool that meets your service, support, and cost requirements and then integrate Acu-Rite Solutions to maximize its accuracy.

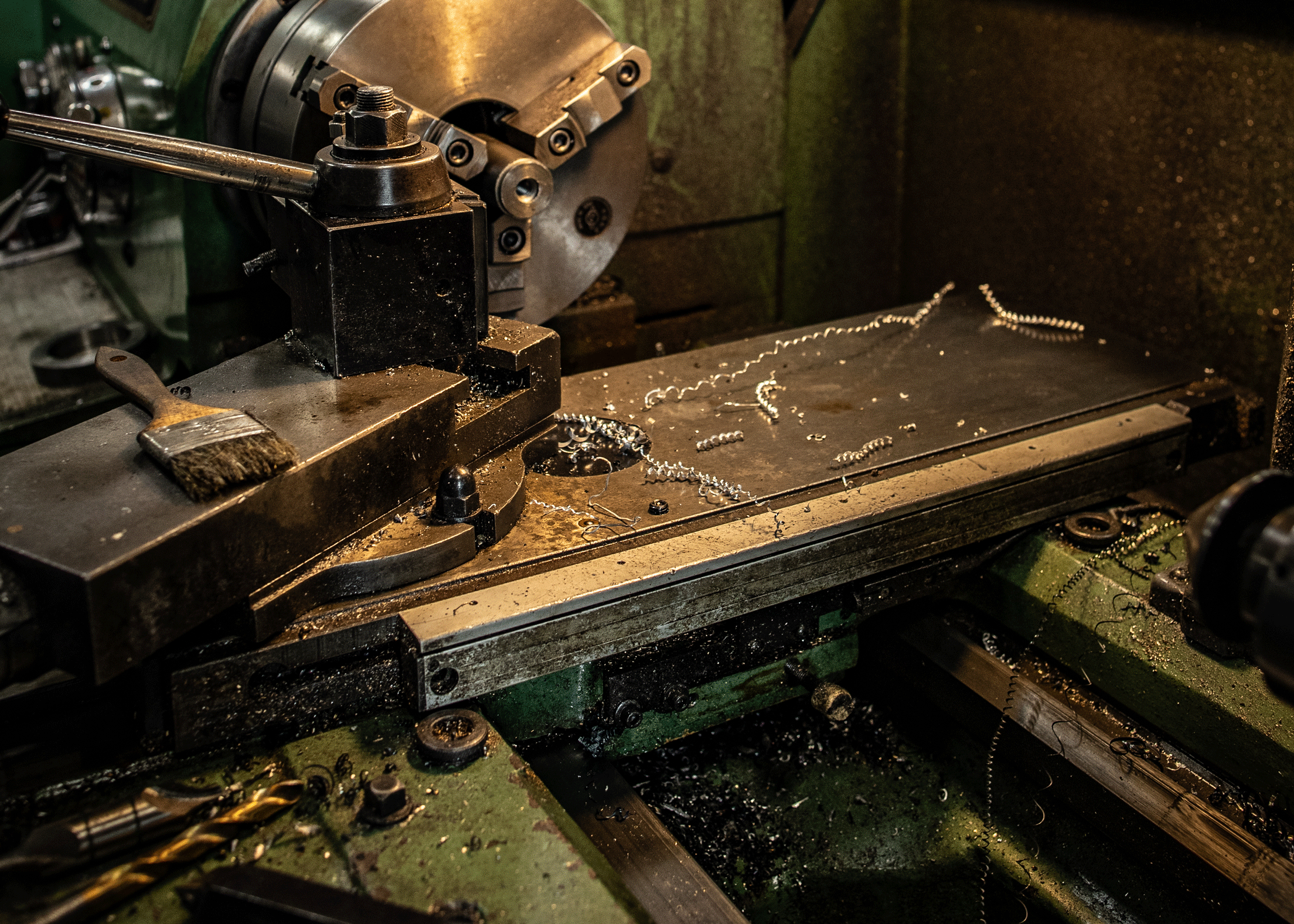

- Retrofits: Add Acu-Rite Solutions to improve machining performance without investing in entirely new machinery, extending equipment lifespan.

The CNC control and DRO systems are designed to be compatible no matter which machine tool you choose, providing superior positioning accuracy that improves machining quality and efficiency. This level of compatibility allows machinists to enhance the performance of various machine tools across diverse applications.

For example, the American Precision Museum installed a MILLPWRG2 CNC control on its 1960s Bridgeport mill. The retrofit allows the museum to demonstrate the Bridgeport mill’s original capabilities and advanced precision and efficiency when using the MILLPWRG2.

Affixing a DRO to the machine tool correctly is critical for achieving optimal functionality and accuracy. Our custom mounting bracket kits simplify the installation.

You can choose from six DRO mounting bracket kits for various mounting positions:

- Tilt-swivel

- Short arm

- Long arm

- U-bracket with T-joint

- Single-position stand

- Frame panel mount

Linear Encoder Mounting Bracket Options

Our custom mounting bracket kits also maximize the accuracy of Acu-Rite Solutions linear encoders—without having to modify standard bracketing or form your own.

DRO Mounting Bracket Options

Scale mounting bracket kits are available for these types of machine tools and dozens of brands, both past and present:

- Mills: Knee, bed, quill, crossfeed, and longitudinal

- Lathes: Crossfeed and longitudinal

- Grinders: Cross feed and down feed

“We know Acu-Rite Solutions DROs are easy-to-use and reliable products. We found the DRO quite easy to retrofit onto the machine and were thrilled that the mounting brackets and all were included in the kit.”

Rich Pekelney

Trustee and Volunteer

San Francisco Maritime National Historical Park Association

Linear Encoders for Nearly Every Machining Environment

Over 1,000,000 precision glass scales from Acu-Rite Solutions are in use today. That is because pairing our CNC control and DRO systems with an Acu-Rite Solutions linear encoder boosts the performance of nearly every manual machine tool.

Our durable linear encoders provide repeatable, high-accuracy feedback in industrial facilities and job shops to home workshops and schools. The Southern Illinois University College of Engineering uses Acu-Rite Solutions DROs and linear encoders to help students prepare manufacturing and design projects. One DRO system is on a Bridgeport mill in the college machine shop, where dozens of students use it almost daily.

Acu-Rite Solutions linear encoders are the most reliable on the market. They are designed, manufactured, and tested to withstand even the harshest machine shops—for years on end. In addition to flexible mounting features, they feature armored cable, a rugged scale case, and an IP rating of 53 when installed per instructions.

The precision glass scale integrates advanced optical technology developed by HEIDENHAIN, which resists size, shape, and density changes regardless of temperature and humidity variations. The result is improved machining quality, fewer errors, and less scrap and downtime.

From tight and restricted spaces to large machine tool applications, Acu-Rite Solutions linear encoders are compatible with diverse machining environments:

- SENC 50 Linear Encoder: Highly compact dimensions for tight and restricted spaces with travel lengths of 1 – 20”.

- SENC 150 Linear Encoder: A compact yet robust design for almost any application (including EDMs, grinders, lathes, mills, and inspection equipment), with travel lengths of 2 – 120”.

- LMF 9310 Linear Encoder: Virtually impervious to contaminants, a multi-section linear encoder with travel lengths of 127 – 773” for large machine tool applications.

Comprehensive Product Support

Integrating Acu-Rite Solutions CNC control and DRO systems is easy, especially when you tap into our comprehensive product support resources. You can access our vast network of channel partners and HEIDENHAIN technical support representatives for guidance during product installation, troubleshooting, and operation. We will help you maximize your equipment’s accuracy, functionality, and lifespan.

Channel Partner Support

Our channel partners have significant experience in manufacturing and machine automation, so they are prepared to meet the demands of diverse machining applications. They are exceptionally knowledgeable about Acu-Rite Solutions products, and many have partnered with us for decades.

Acu-Rite Solutions channel partners provide in-person support for the lifetime of our technologies. Each is factory-certified and authorized to purchase, install, and service all of our products. We have dozens of channel partners across North America, and you can use our channel partner locator map to find one near you.

HEIDENHAIN Support

You can also get help with Acu-Rite Solutions products from HEIDENHAIN technical support representatives based in North America:

- Immediate Support: Contact our Technical Support Call Center at (847) 490-1191 from 7 a.m. to 5 p.m. CT, or email us at ac***************@********in.com. (Visit our support page to view the phone numbers for Canada and Mexico.)

- Training Classes: Attend in-person or live online training classes and learn how to operate your new Acu-Rite Solutions product.

- On-demand Resources: Visit the support section of our website to view product tips and instructions, documentation, registration forms, and software updates. This is where you will find the installation guides for our custom bracket kits.

Unlock Next-Level Precision with Acu-Rite Solutions CNC Control & DRO Systems

Acu-Rite Solutions’ precision CNC control and DRO systems integrate seamlessly with manual machine tools new and old. Their superior compatibility allows machining professionals, hobbyists, and educators to tailor machine tools to their specific needs and expand their capabilities. No matter what machine tool you use or the machining environment you work in, choosing an Acu-Rite Solutions CNC control or DRO system will improve your accuracy, efficiency, and quality.

Contact a channel partner today and explore Acu-Rite Solutions for your application.