A family-owned glass fabricator in Ohio expanded its machining capabilities with the MILLPWRG2, allowing it to handle a higher volume of work and more technically demanding jobs while significantly reducing programming and setup time.

Background

Delivering Precision Glass Parts for Demanding Applications

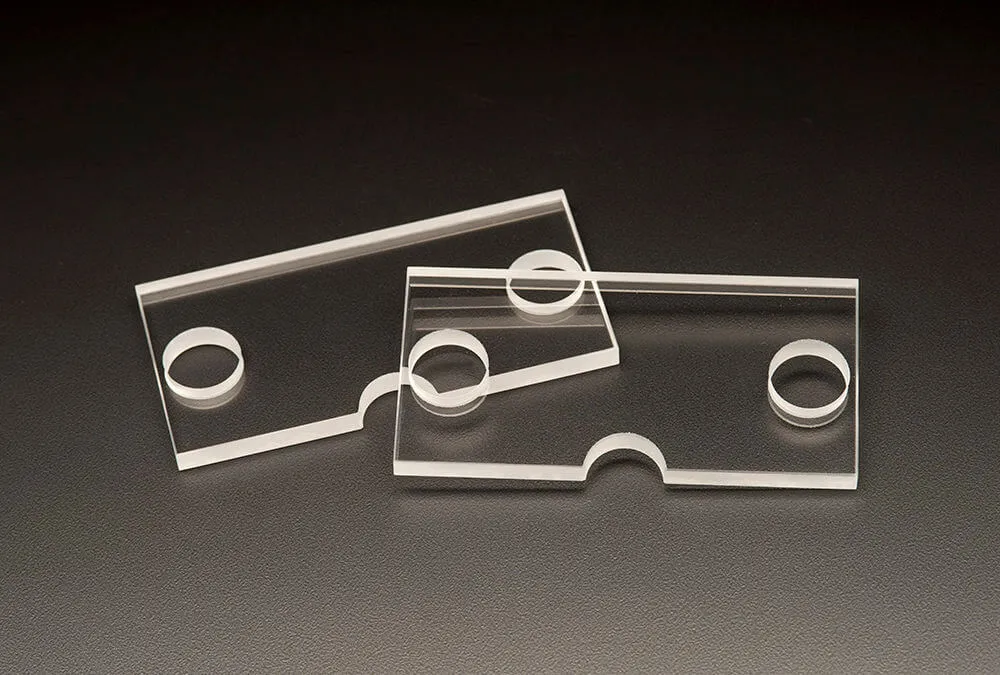

Machined Glass Specialists (MGS) is a family-owned custom fabricator of high-performance glass materials like fused quartz, fused silica, and borosilicate. Since its founding in 1989, MGS has continually advanced its techniques, equipment, and efficiency to create precision glass parts affordably.

From its 15,000-square-foot facility in Ohio, MGS uses proprietary cutting, polishing, and inspection methods to craft one-of-a-kind glass components for industries ranging from semiconductors to medical. MGS parts are produced with the quality and reliability to perform in a variety of high-temperature, high-pressure applications.

Photo Courtesy of Machined Glass Specialists

Challenge

Why Upgrade CNC Controls When the Old Ones Still Work?

MGS wanted to keep pace with increasingly complex fabrication by modernizing its aging equipment—several milling and grinding machines and the legacy Acu-Rite Solutions MILLPWR CNC controls attached to them.

Their MILLPWRs were still performing well after nearly 20 years in service, eliminating human error that could cause costly material and tool waste and lost productivity. But MGS recognized that adopting more modern CNC technology would enhance their machining capabilities and efficiency.

“When it came time to buy new machines and upgrade our legacy MILLPWRs, choosing MILLPWRG2 systems was a no-brainer for us.”

Jason Behm

Supervisor, Machined Glass Specialists, Inc.

Solution

Why Was MILLPWRG2 the Right Fit for MGS’s Evolving Machining Needs?

After years of success using MILLPWR CNC systems, MGS purchased a used machine with a first-generation MILLPWRG2. The team was quickly impressed by how it performed.

MGS needed a CNC control that could provide precision feedback in a dusty environment while adapting to frequent program changes. The MILLPWRG2 met these needs with a high-accuracy glass scale, durable construction, intuitive programming options, and comprehensive support.

The MILLPWRG2 is an entry-level CNC control for precision three-axis machining on knee and bed mills. It’s designed for any job requiring manual and automated machining and can operate as a full-function digital readout system, a programmable CNC control, or both.

When it came time to purchase new mills and grinders, choosing the latest MILLPWRG2 CNC system was a “no-brainer,” according to Jason Behm, supervisor. Behm worked with Ray Ayers at RLA Machine & Tool Sales, an authorized Acu-Rite Solutions channel partner, to purchase Kent mills and grinders with nine MILLPWRG2 systems.

Photo Courtesy of Machined Glass Specialists

| MGS Requirement | MILLPWRG2 Features |

|---|---|

| Accuracy: Gain the precision and speed to deliver on increasingly complex requests more effectively and efficiently. | ● Durable linear encoders provide repeatable, high-accuracy feedback using advanced precision technology from HEIDENHAIN. ● Toolpath previews reduce the risk of programming mistakes, providing a listing and graphic with estimated machining time. |

| Flexibility: Adapt to varying program needs, which change almost every time MGS runs a job. | ● Robust program storage accommodates repeat jobs, while manual mode allows ad hoc adjustments. ● Conversational and G-code programming make the MILLPWRG2 easy to use for machinists, from entry-level to experienced. |

| Durability: Stand up to the high volume of dust created by grinding and drilling glass materials. | ● American-made design and construction for maximum reliability. ● Die-cast metal bezel and enclosure. ● IP ratings of 54 (front) and 40 (back). |

| Support: Gain reliable local support for the lifetime of the product. | ● End-to-end in-person support (purchasing, installation, and service) provided by Acu-Rite Solutions’ factory-certified and authorized channel partners nationwide. ● Live phone and email support from HEIDENHAIN representatives based in North America. ● On-demand support resources on the Acu-Rite Solutions website. |

“The MILLPWRG2 has been game-changing for our business, allowing us to take on more jobs and increasingly complex requirements.”

Jason Behm

Supervisor, Machined Glass Specialists, Inc.

Results

How did the MILLPWRG2 Upgrade Help MGS Say ‘Yes’ to More Jobs?

The MILLPWRG2 has transformed machining capabilities and efficiency for MGS, enabling it to complete more complex jobs efficiently.

One contributor is the DXF file import feature. Before implementing the MILLPWRG2, MGS would turn down specific jobs because drawing programs point by point was so time-consuming. With the MILLPWRG2, MGS can draw components in a CAD program, download the programs as DXF files, and import them into the MILLPWRG2, saving time and scrap due to human error.

Behm estimates that the MILLPWRG2 has helped cut programming and setup time by at least half. In some cases, it has reduced setup time from five hours to just 10 minutes.

Today, MGS uses its nine MILLPWRG2 CNC systems to cut profiles, slots, pockets, and radii, often with tight tolerances and intricate geometry. For example, MGS recently fabricated a quartz nozzle measuring three-quarters of an inch in diameter by one-and-an-eighth inches long. The design involved drilling numerous holes, each with a diameter of 50 thousandths of an inch, at a 30-degree angle on the sides of the nozzle. The holes converged at the center of the part into another 50-thousandths hole. There were various steps at the ends of the part as well.

Upgrading to the MILLPWRG2 unlocked next-level efficiency for MGS, allowing it to continue producing superior workpieces while saving time and cost associated with setup, scrap, and other non-productive operations.

Photo Courtesy of Machined Glass Specialists

“If you’re doing three-axis work, I think the MILLPWRG2 his just the way to go.”

Jason Behm

Supervisor, Machined Glass Specialists, Inc.

Are you ready for an affordable upgrade to your mill function and lifespan? Learn more about precision machining with the MILLPWRG2.