SCHAUMBURG, IL (December 2014) — Absolute and incremental positioning are used interchangeably when discussing the position values of the DRO. Both absolute and incremental position methods give the operator greater flexibility when machining a part.

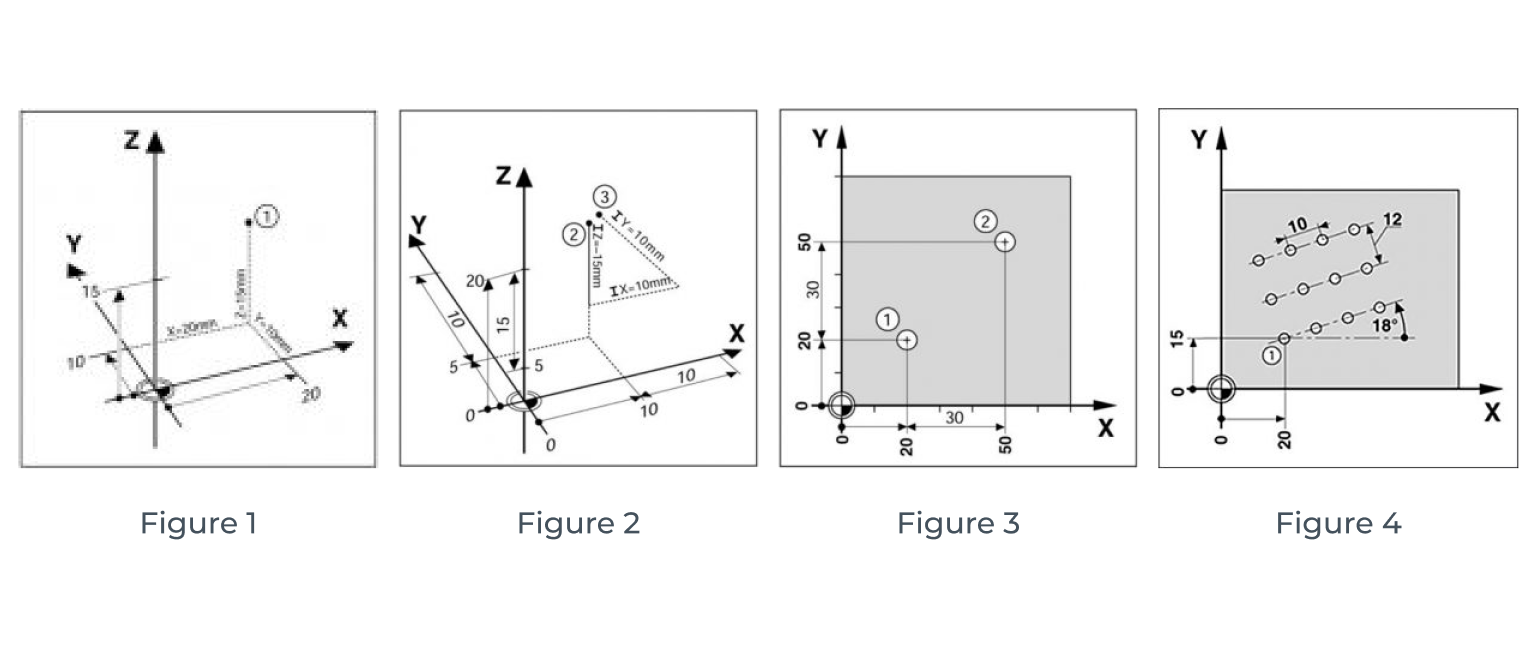

Absolute coordinates are defined as each position on the work piece is unique. Using Figure 1, the absolute coordinates for position 1 are X = 20 mm, Y= 10 mm and Z = 15 mm.

With incremental coordinates, the last point traveled to becomes the new reference point on which the operator bases his next move. In Figure 2, the operator wants to move from position 2 to position 3. The operator would input the following values to move to position 3 incrementally.

XI = 10 mm

YI = 5 mm

ZI = 20 mm

Incremental coordinate positioning is very useful tool when the operator doesn’t want to do addition or subtraction to figure out the absolute coordinates. Figure 3 shows how the operator can put in XI = 30 and YI = 30 instead of doing the addition to find out what the absolute coordinate of position 2 is when moving from position 1.

Also, incremental coordinates are used with bolt-hole patterns so the operator doesn’t have to know the exact coordinates of each bolt hole but rather move until each axis display is zero before drilling a hole.

In conclusion, each coordinate system has its benefits and it is truly up to the operator to take advantage of the benefits of each coordinate measurement system.