As an emphasis on North American manufacturing continues to grow, so does the need for skilled staff. That’s why one of the goals of Acu-Rite Solutions management continues to be supporting area schools’ manufacturing programs with its U.S.-made and easy-to-use products for controlling machine tools, as well as offering deep discounts to educators to use them.

Backed by HEIDENHAIN’s constant innovation and made in America for over 60 years, Acu-Rite Solutions high quality digital readouts (DROs) and CNC controls are regularly making their way into school machine shops and manufacturing programs. This includes being found in high schools, vocational training centers and colleges.

Educators using Acu-Rite Solutions often comment that they like the large product line and long-lasting, reliable options available, from both the entry-level and complex digital readouts to CNC controls for mills and lathes. Other comments include that they are keen on the fact that all the products are designed in a logical progression, so they build upon each other making it easy to transfer existing skills and to develop a practical machining curriculum. According to Acu-Rite Solutions Product Manager John Parker: “Other DRO and CNC manufacturers can’t say that.”

Horry-Georgetown Technical College

One example of a successful manufacturing education program in operation is Horry-Georgetown Technical College (HGTC) in South Carolina. Here, Acu-Rite Solutions DROs and controls are on much of the equipment in their large Machine Tool Lab in their Advanced Manufacturing Center. “Our program actually takes you from the foundational skills all the way through the actual completion of programming of a CNC,” said HGTC Machine Tool Instructor Richard Brown. “The

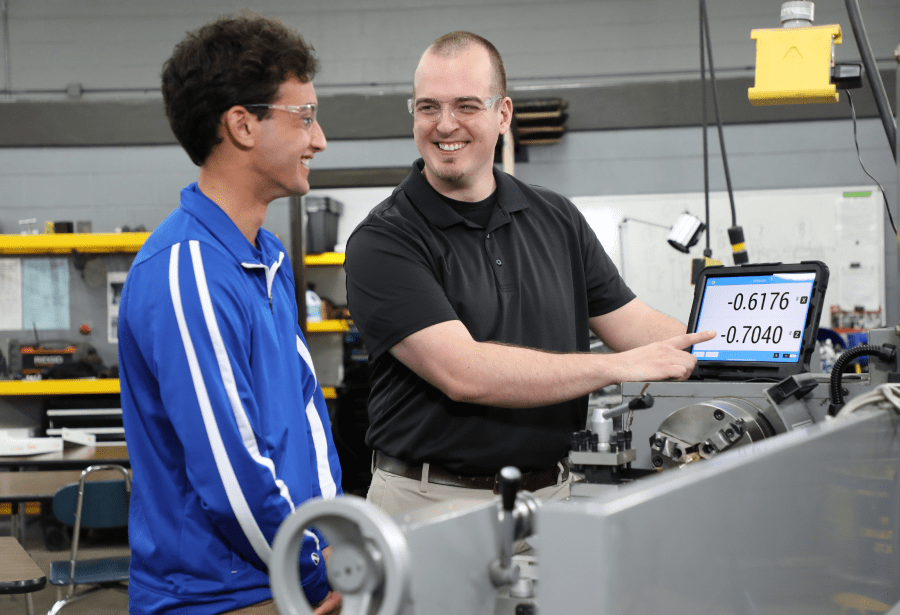

Acu-Rite Solutions is good to teach on because it gives the student right in their face what is happening as they move the dials. And once they get that, you no longer see them watching the dials. You see them just watching their screen and they know exactly where it’s at as they are cutting the part. It takes a student about 15 minutes to learn the Acu-Rite Solutions.” According to HGTC’s Dean of AVP Academic Affairs Brandon Haselden: “Acu-Rite Solutions is an industry standard. The liability, the longevity, the accuracy of the systems are definitely there. We’ve had (Acu-Rite Solutions) systems here that are five or six years old, and we’ve never had an issue. And that’s extremely important from an investment perspective.” Click here to see the three-minute Horry-Georgetown video.

Randolph Community College

Since Acu-Rite Solutions components are a common standard in the machining industry, students learning to use them naturally have an advantage when transferring to the work world. Garret Parker, head of the Computer-Integrated Machining department at Randolph Community College in North Carolina, confirms: “Our partnership with Acu-Rite Solutions has evolved over the years by listening to our advisory board that drives our program. We go out and visit their industries, see what kind of equipment they have and base our curriculum on what they have so we can better prepare our students for the real world…. The majority of our manual and CNC-controlled machines have an Acu-Rite Solutions control or digital readout.”

And when asking about Randolph’s use of the Acu-Rite Solutions controls, G. Parker continued: “The Acu-Rite Solutions control is a perfect match for students. The layout of the control is very user-friendly. The students can quickly go to the control for the first time and understand how the control works, what it’s supposed to do, and they can quickly pick up and write a simple program to be able to produce a part. It’s a win-win for the student and the instructor.” Click here to see the three-minute Randolph video.

Deep discounts on Acu-Rite Solutions products are offered to educators through Acu-Rite Solutions School Discount Program. Ask your local distributor for more information or contact Acu-Rite Solutions directly to learn more.