Your precision machining partner

A Legacy of Precision

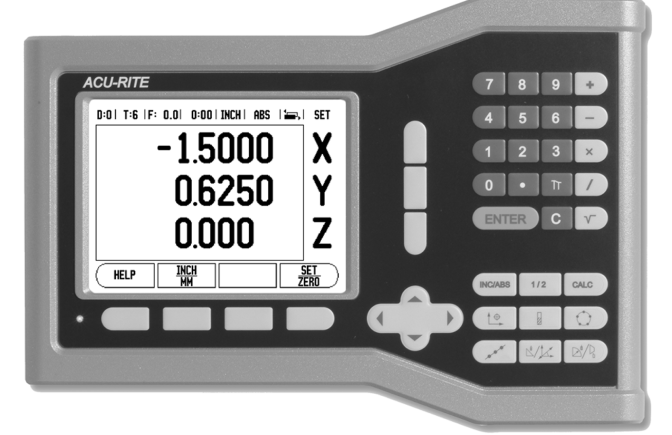

For over 50 years, Acu-Rite Solutions has been a trusted name in digital readouts (DROs), linear encoders, and CNC controls. Our products have shaped how machinists, educators, and manufacturers approach precision, making workflows simpler, faster, and more reliable. From small shops to technical schools to large production facilities, Acu-Rite Solutions has always stood for accuracy and usability.

Backed by HEIDENHAIN

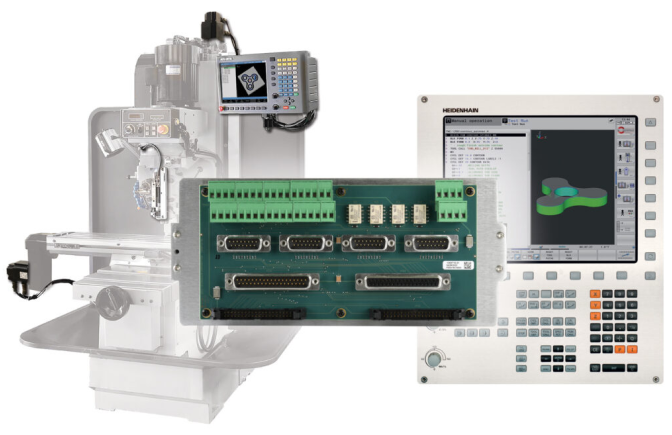

Acu-Rite Solutions is part of the HEIDENHAIN family of brands, a global leader in motion control and precision measurement technology. This partnership combines the reliability of U.S.-based service and support with the engineering excellence and global innovation of a worldwide technology powerhouse.

From Acu-Rite to Acu-Rite Solutions

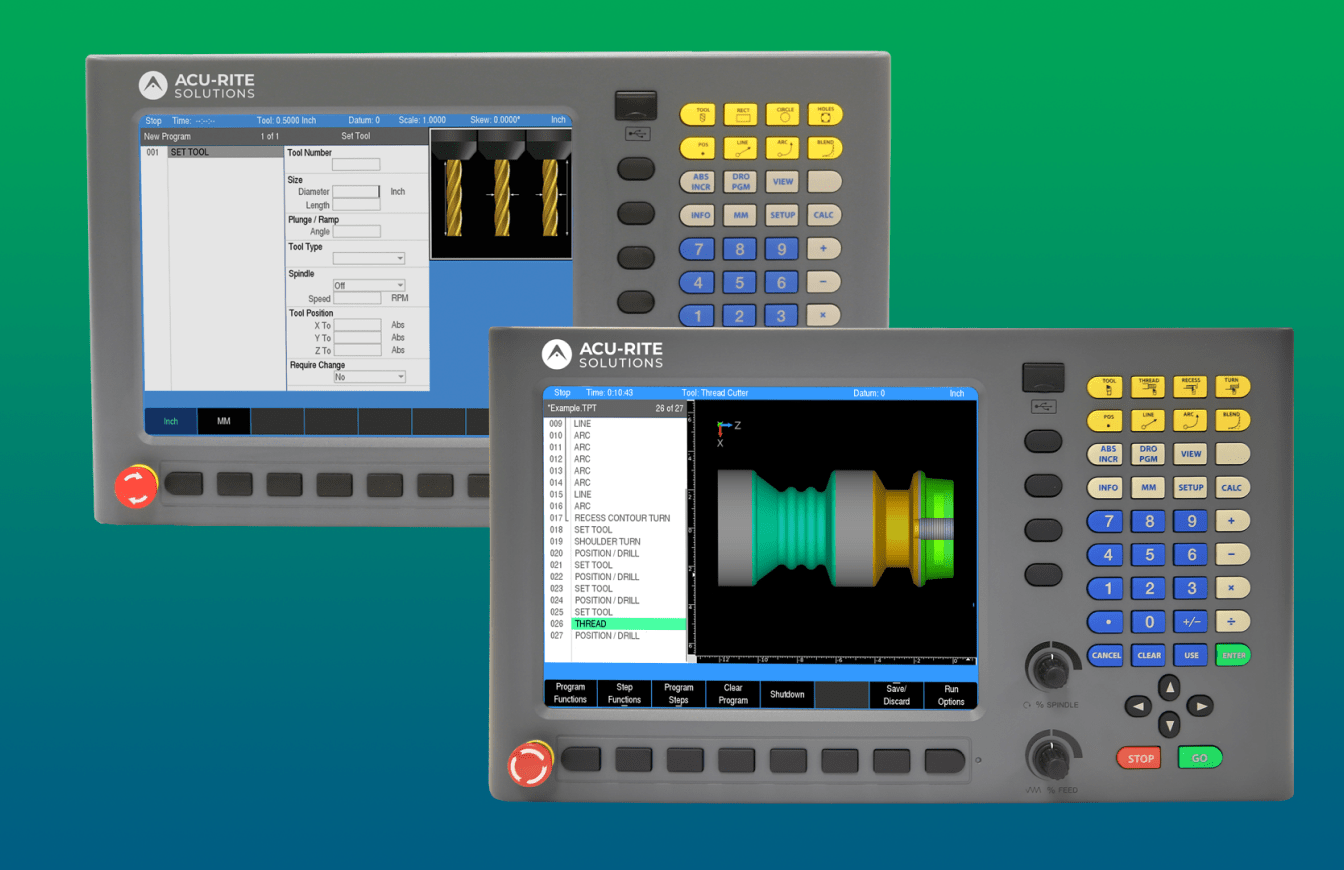

In 2024, we rebranded as Acu-Rite Solutions, marking our evolution from a product provider to a solutions partner. Today, we deliver more than DROs and controls—we provide integrated packages that include encoders, accessories, training, and responsive support. This shift reflects our commitment to helping machinists and educators meet the challenges of modern manufacturing and workforce development.

Supporting Machinists and Educators

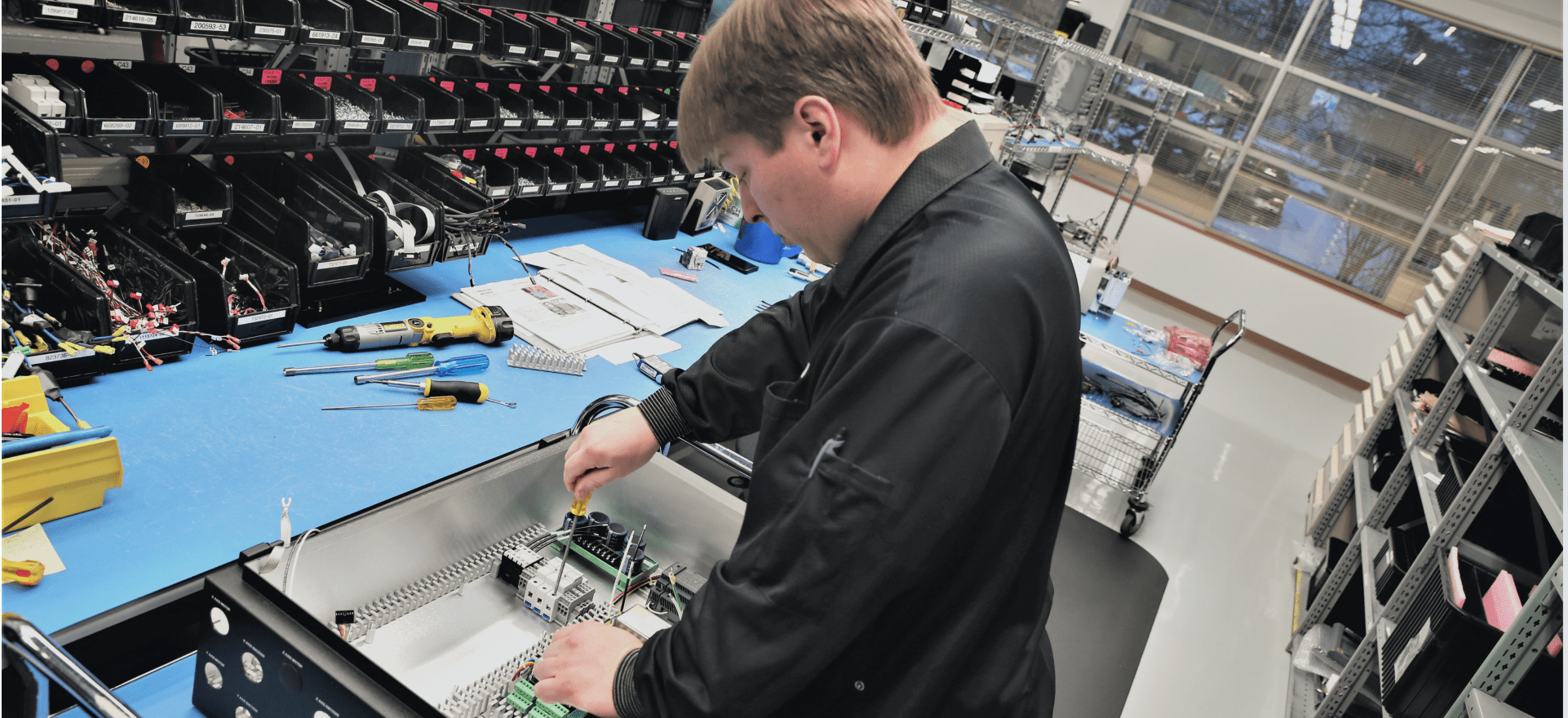

Our solutions play an important role on both the shop floor and in the classroom. In education, Acu-Rite Solutions helps students gain confidence with industry-standard equipment. In professional shops, our products reduce costly errors, improve productivity, and withstand the daily demands of machining. Whether it’s a retrofit project or an advanced training program, we deliver the tools and support needed to succeed.

Our Commitment

At Acu-Rite Solutions, we believe that every measurement matters. That philosophy drives our focus on durability, accuracy, and ease of use—backed by responsive technical support and a dedication to continuous improvement. We’re here to provide solutions that not only meet today’s needs but also prepare machinists and educators for tomorrow.

Our Journey

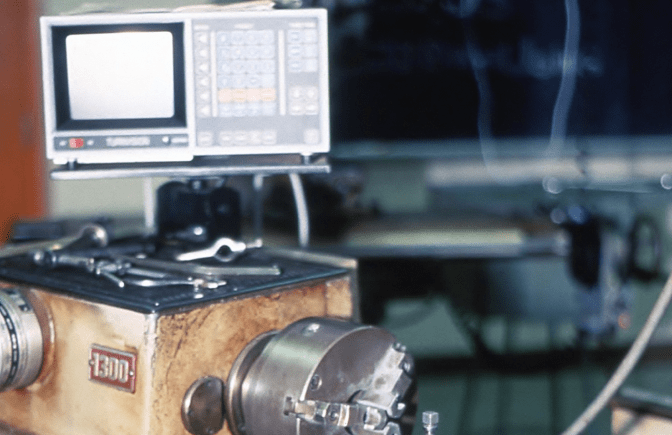

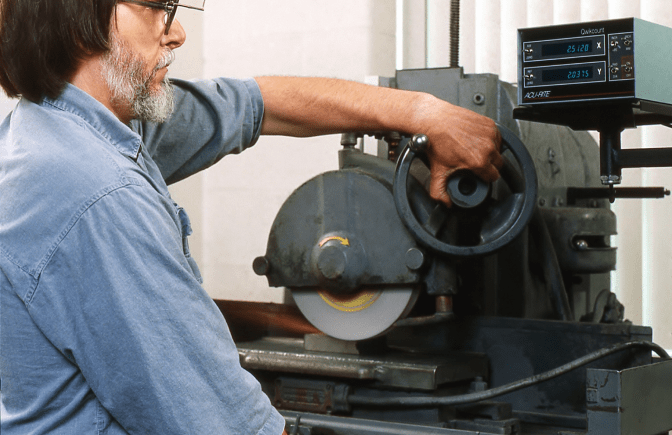

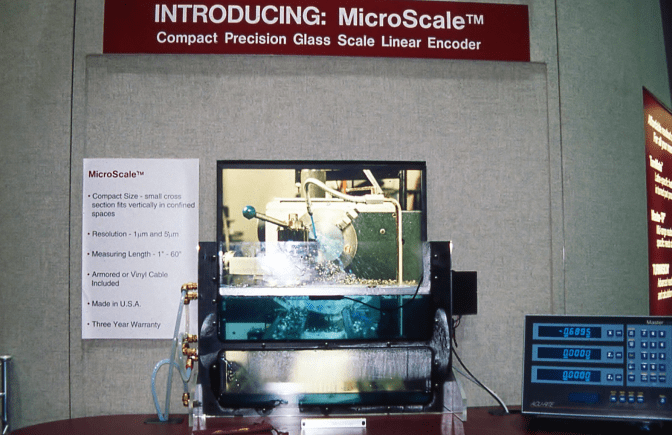

The story of Acu-Rite Solutions is one of steady innovation and growth. In the 1960s and 1970s, we pioneered DROs that revolutionized precision measurement. The 1980s and 1990s brought the introduction of linear encoders and CNC controls, further expanding our reach. By the 2000s, Acu-Rite Solutions had joined the HEIDENHAIN family of brands, gaining access to global research and development resources. In the 2010s, our products became a mainstay in machinist training and technical education.

In 2024, we reintroduced ourselves as Acu-Rite Solutions, reflecting a broader mission: to deliver complete, integrated solutions for modern manufacturing. Today, we continue to combine our proud heritage with new technology, serving machinists, educators, and manufacturers across North America with precision, reliability, and innovation.

Acu-Rite Solutions creates infinite machining possibilities, from re-creating classic aircraft parts to prototyping a line of popular tattoo machines.

Our easy-to-use precision technologies help machinists, educators, and hobbyists achieve better positioning accuracy while saving time and cost. Transform your machining capabilities and grow machine tool profitability.

Machine superior workpieces

Produce more with fewer resources

Gain a reliable, supportive machining partner

Explore our legacy of technical ingenuity

Acu-Rite Solutions is backed by the continuous innovation of HEIDENHAIN, a world leader in precision measurement and control. Watch how we help technological heroes bring their big ideas to life as part of the HEIDENHAIN Family of Brands.

Transforming manual machining for 60+ years

Customers have trusted Acu-Rite Solutions to enhance their machining capabilities for decades. Designed and built in America, our intuitive and durable CNC controls, digital readouts, and encoders boost accuracy and productivity. Browse highlights of our history of product development.