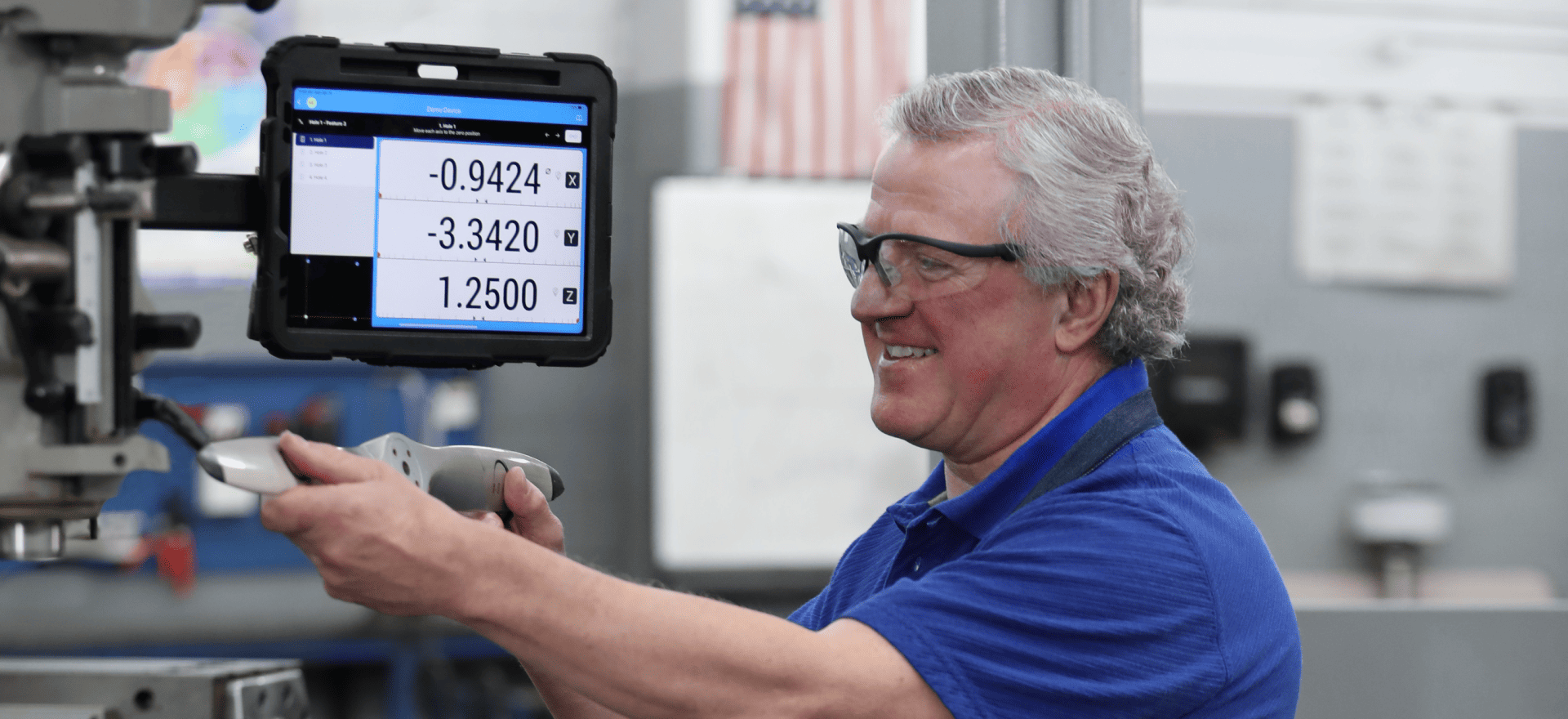

Achieve next-level machining accuracy and efficiency

Acu-Rite Solutions DRO systems equip machinists with the most advanced precision technologies available. Backed by the continuous innovation of HEIDENHAIN, they eliminate the need for manual calculations to improve machining accuracy, efficiency, and profitability.

Enhance workpiece quality

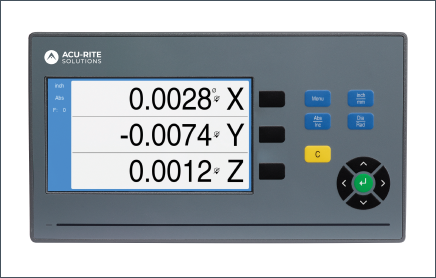

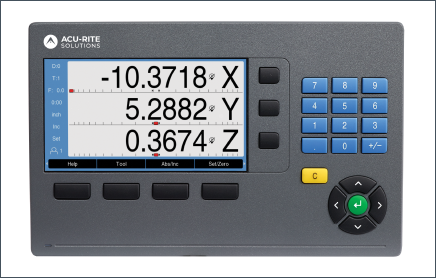

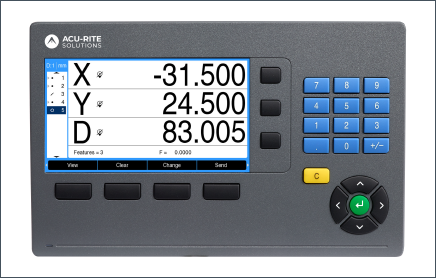

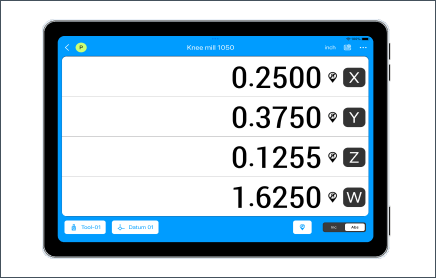

Acu-Rite DRO systems for milling deliver real-time position feedback to improve accuracy, reduce scrap, and achieve tighter tolerances. Whether you’re making rough cuts or finishing passes, our systems help you create consistently high-quality workpieces.

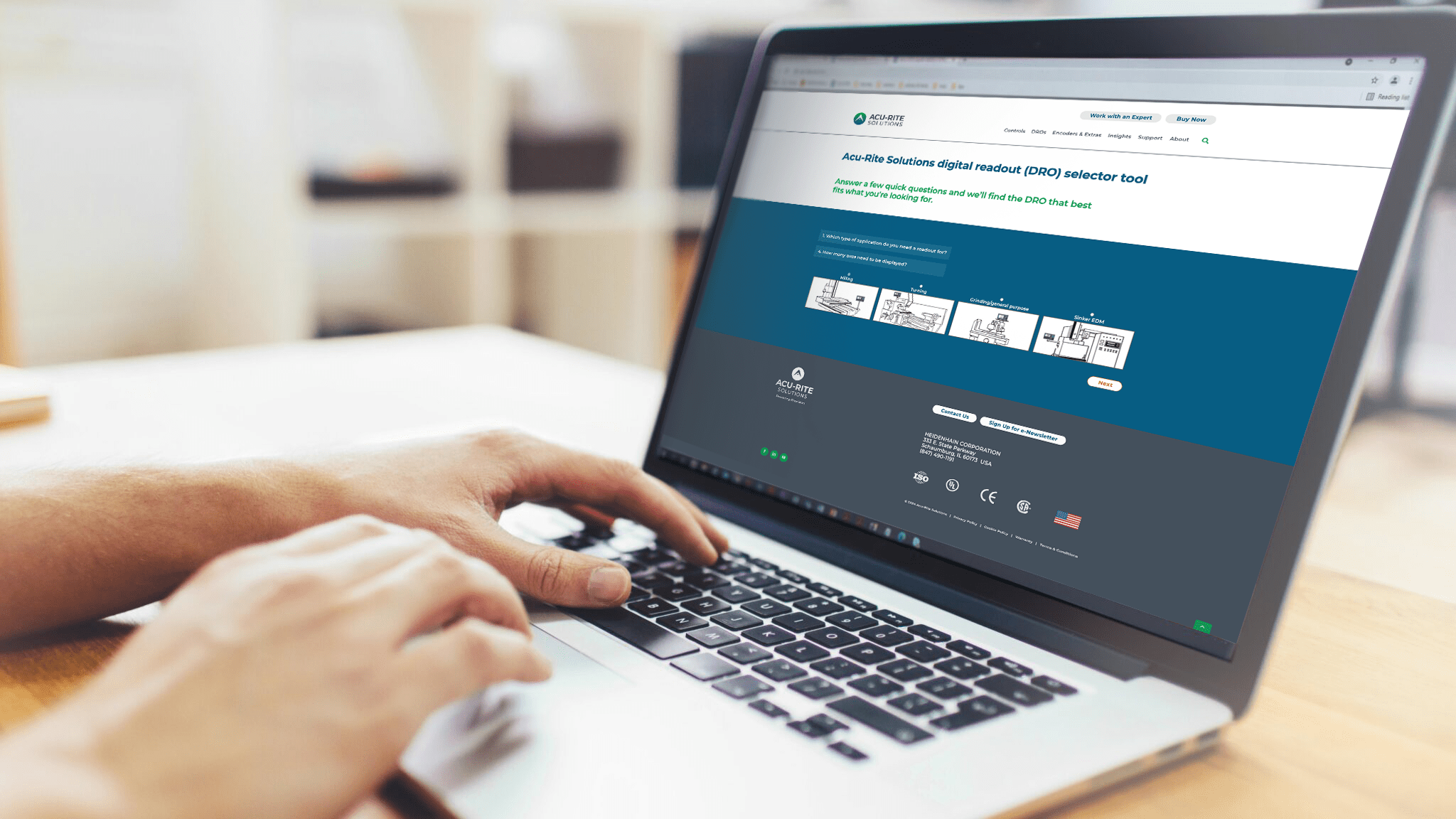

When choosing a DRO for milling, consider your scale type (glass or magnetic), preferred resolution, number of axes, and display features. Acu-Rite makes it easy to find the right fit for your machine, so you can mill with confidence from start to finish.

Pre-programmed common cycles

Specific functions for milling and turning

Long-distance legibility via dynamic zoom

Machine more with less

With an Acu-Rite Solutions DRO, machinists from entry-level to experienced can be more efficient. The intuitive design makes our DROs easy to install, learn, and operate, saving time and cost.

Large, legible displays adjust to ambient lighting

Graphical and conversational dialog guidance

0–99 tool offsets/diameters

Support for 15+ languages

“Easy to use” DRO systems

“We know Acu-Rite Solutions DROs are easy-to-use and reliable products. We found the DRO quite easy to retrofit onto the machine, and were thrilled that the mounting brackets and all were included in the kit.”

Rich Pekelney

Trustee and Volunteer

San Francisco Maritime National Historical Park Association

Built to be reliable and versatile

Acu-Rite Solutions DRO systems are designed and built in the USA. They produce repeatable accuracy with machine tools new and old, for applications from simple to complex, and in even the harshest machining environments.

Rugged hardware and IP-rated seals

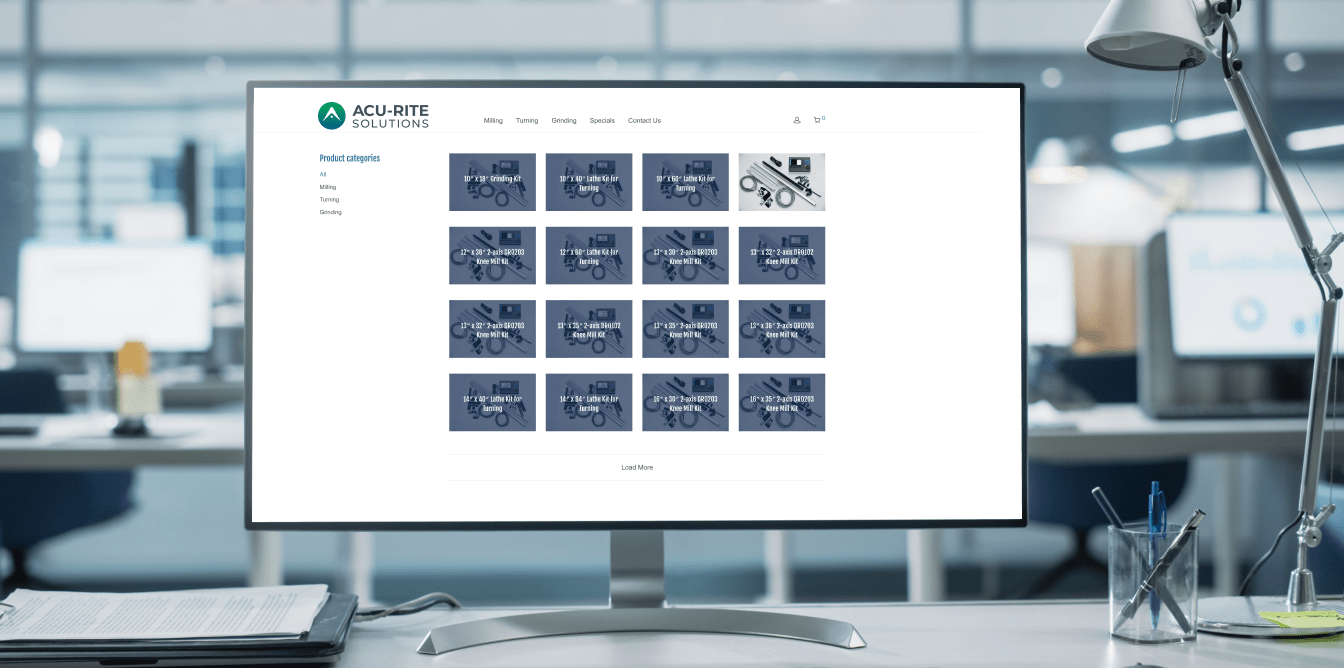

Retrofit 100+ machine makes and models

Time to see ROI averages < 30 days