Entry to advanced: A machinist’s career growth via Acu-Rite Solutions

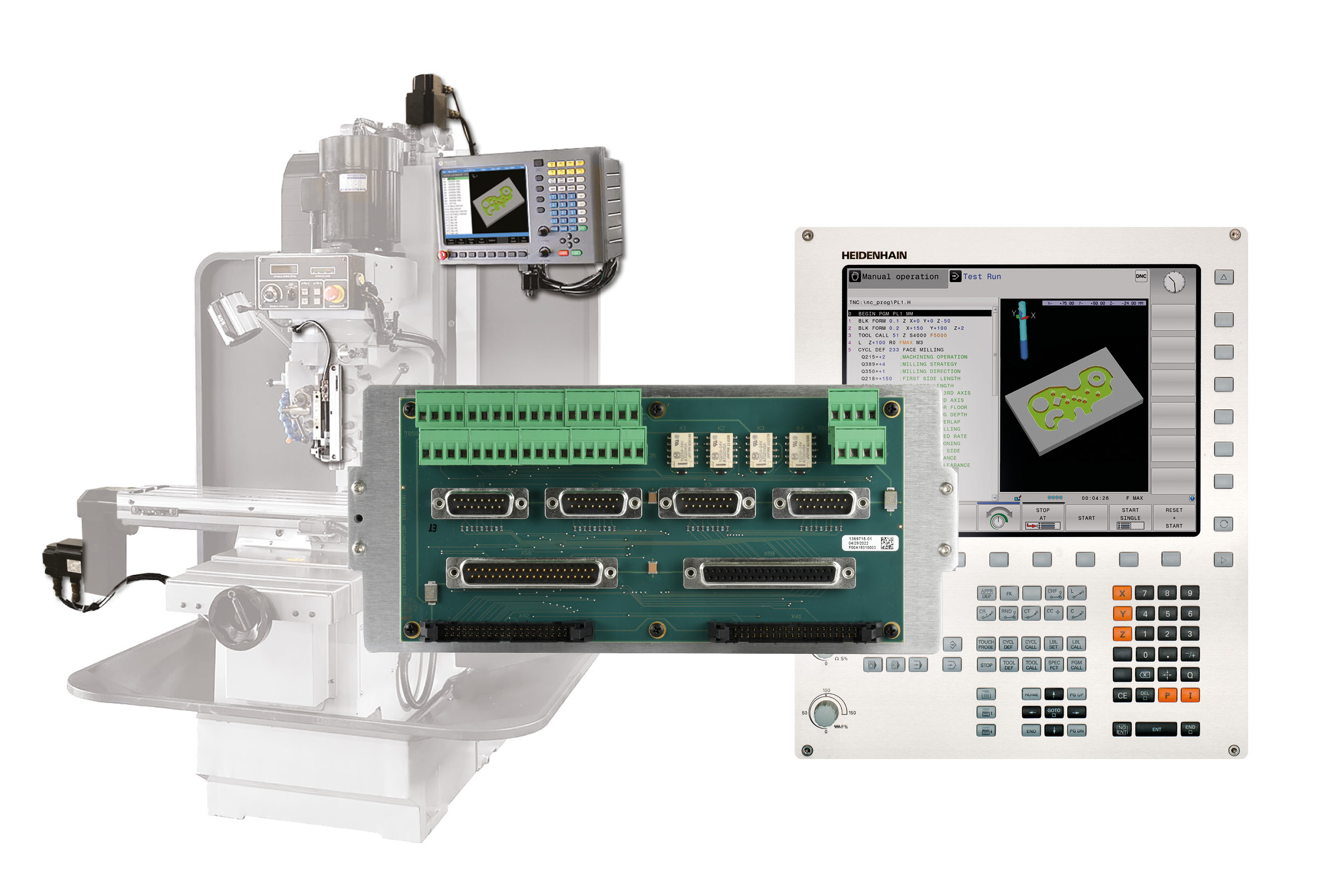

Education and training are essential and unending in the world of manufacturing. Whether just beginning training or being a seasoned machinist, it’s crucial to keep skills up-to-date and to adapt to advancing manufacturing technologies. With the right training and tools, manufacturers can unlock the ability to run more advanced machines and achieve greater success in their field. The Acu-Rite Solutions product catalog allows learners to grow into and layer on more advanced features as they master the basics. Richard Brown, Machine Tool Instructor at Horry-Georgetown Technical College, shared his perspective on progressive product training at the college: “The program actually takes you from the foundational skills all the way through completion of programming CNC” … “Here we feel like you need the foundational skills so that if something goes wrong with the program, you know how to adjust it. Acu-Rite Solutions is good to teach on because it gives the student, right in their face, what’s happening as they’re moving the dials. Once they get that, you no longer see them watching the dials. You see them just watching the screen and they know exactly where it’s at when they’re cutting the parts.” You can support a machinist’s career path, from entry-level to advanced, by pairing the trainee with various products in the Acu-Rite Solutions catalog. Let’s step through the sample progressive product training below. Entry-Level: Manual Input Systems One of the first steps in manufacturing education is gaining experience with manual machine tools. This entry-level exposure allows individuals to learn the fundamentals of machining, including tool selection, work holding, and toolpath creation. For trainees newer to manufacturing, Acu-Rite Solutions offers a range of entry-level manual input systems that are ideal for shop classes, production environments, and small shops. The DRO100, DRO203, DRO300, and droPWR are digital readout systems that allow users to quickly and accurately measure workpiece dimensions. The TURNPWR and MILLPWRG2 systems are CNC retrofit packages that can be added to existing manual machine tools to enable CNC capabilities. By mastering these manual input systems first, trainees will establish a foundational understanding of basic machine functions. [...]