Powering precision in every manual machining application

For over 60 years, our customers have unlocked next-level machining accuracy and efficiency with Acu-Rite Solutions. These are stories of professionals seeking higher production, educators inspiring the next generation, and hobbyists pursuing their passions.

“[The MILLPWRG2] is one of the best, most economical, control systems I’ve seen. It has been and continues to be a great production and business investment for me.”

Burl Rogers

Owner

Burl’s Aircraft, LLC

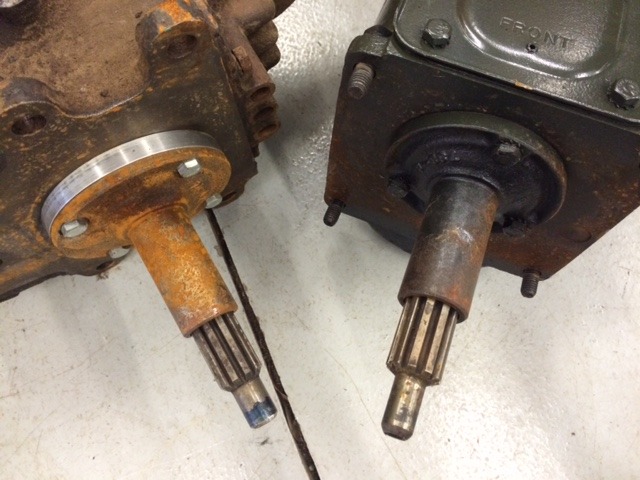

Professional Machining Applications

Machining professionals count on Acu-Rite Solutions to create everything from classic aircraft components to luges for Team USA. Our reliable technologies and support help machinists, engineers, and job shop owners improve their machining capabilities and quality.

“The new Acu-Rite Solutions DRO on the mill in our general shop was put on one of our least-used pieces of equipment, which has now turned it into one of our most used.”

Nick Sjoberg

Graduate Assistant

Southern Illinois University College of Engineering

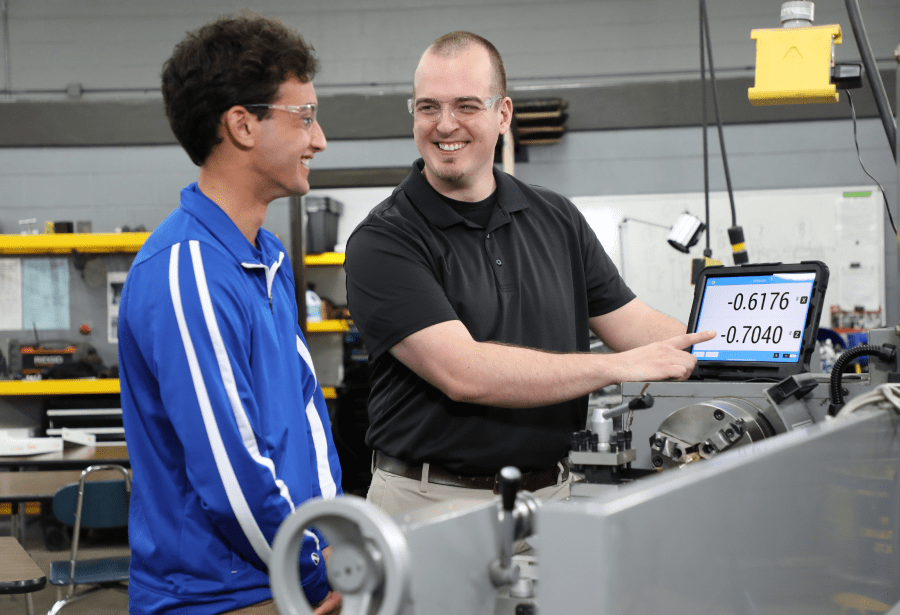

Education Applications

Colleges and universities partner with Acu-Rite Solutions because we help prepare students for real-world engineering and machining challenges. Our products are easy to install, learn, and operate and are built to last on 100+ machine makes and models.

“The tools in Acu-Rite Solutions MILLPWRG2 turn us loose to build anything we can imagine.”

Bill Hutchison

Auto Hobbyist

Retired Tech Industry Executive

Hobby Applications

Hobbyists choose Acu-Rite Solutions to engineer their creative visions, from hot rod parts to tattoo machines. Because our technologies are simple to install and operate, hobbyists with almost any manual machine tool can use them to save time and money.

What will you create with Acu-Rite Solutions?

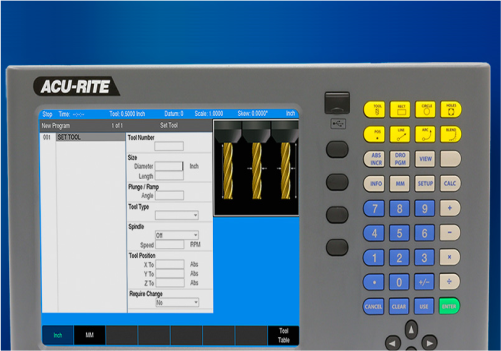

Precision CNC Controls for

Milling and Turning

Versatile DROs for Milling,

Turning, Grinding and Boring

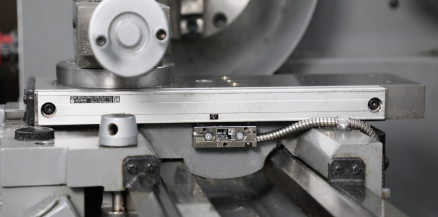

Durable Encoders and Extras

for Maximum Accuracy