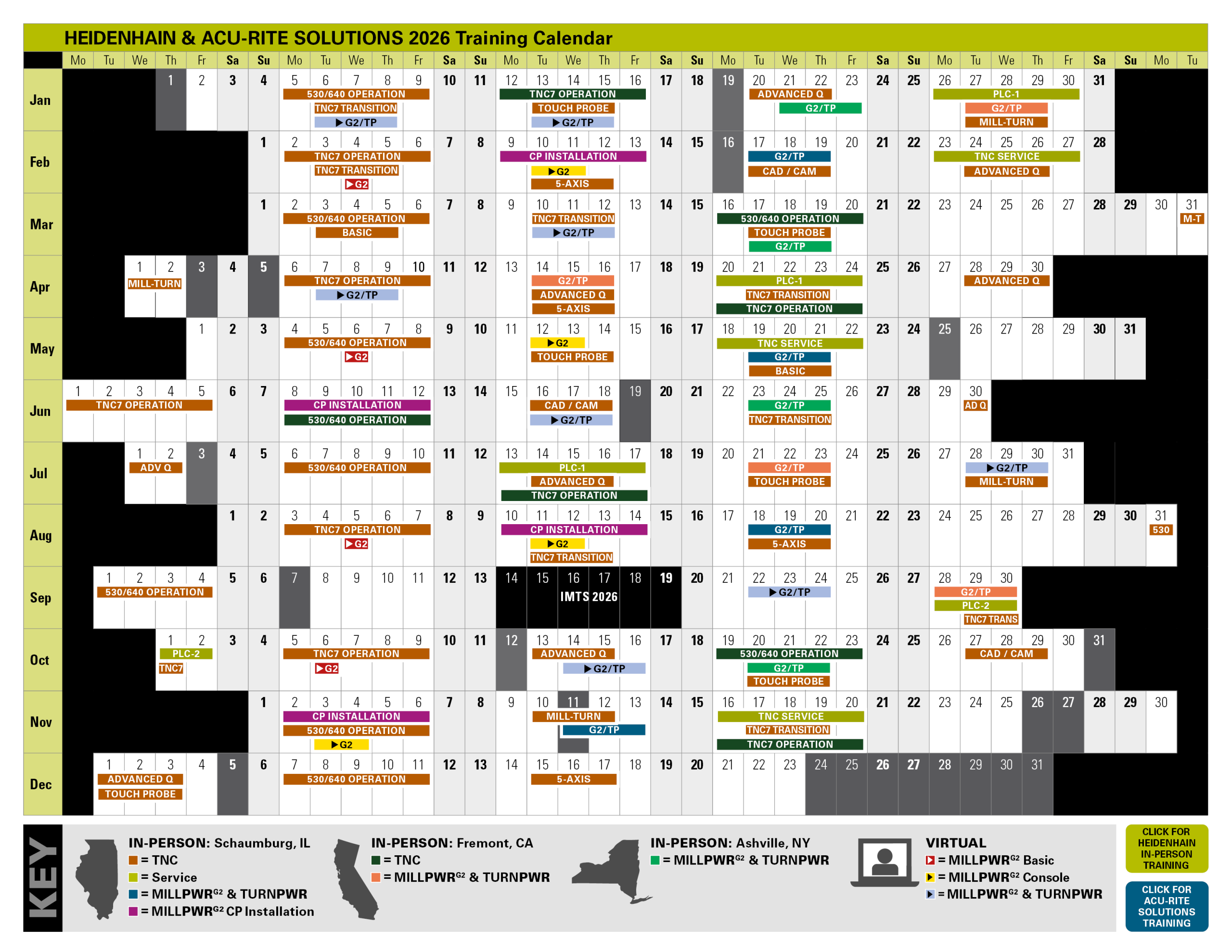

2026 training calendar released

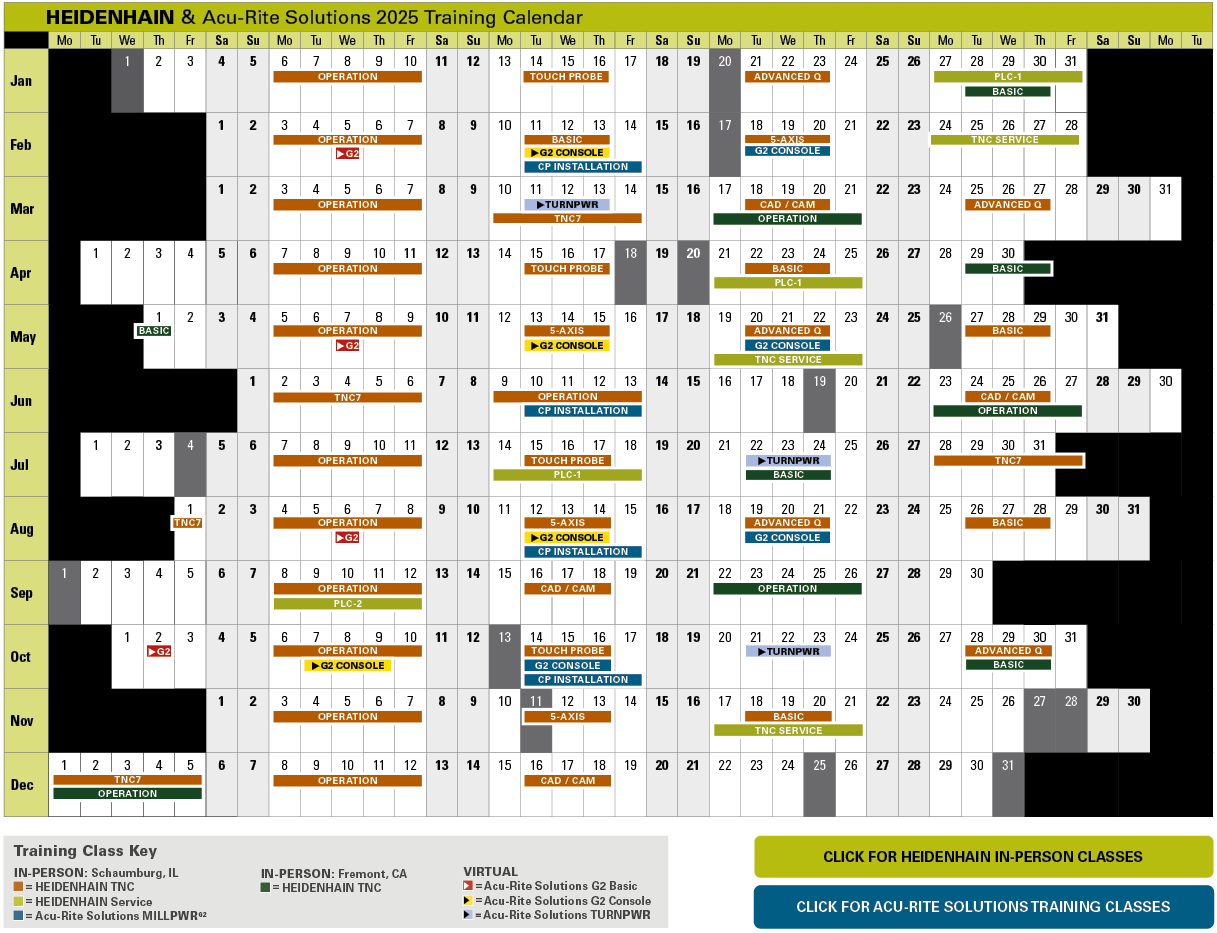

2026 training calendar released Click image to open interactive PDF Technical qualification and continuing training are indispensable for achieving technological improvement and securing the future of a company and its employees. HEIDENHAIN CORPORATION provides technical training covering installation and programming as well as general training for distributors and end-users in our locations in Schaumburg, IL, Fremont, CA and Ashville, NY. Classes include engaging presentations and live machine demonstrations with the latest CNC and motion control from HEIDENHAIN. Click the 2026 TNC Training Calendar above to open an interactive PDF. Once there, you can click on a class to view detailed information and a registration form.