For over 60 years, ACU-RITE has developed the most trusted CNC control and digital readout (DRO) systems in the machine tool marketplace. Whether setting up a new machine tool or retrofitting an old one, an ACU-RITE control or DRO paired with an encoder forms an economical and effective system for precision machining.

Over one million ACU-RITE glass scales are in use today. So, why do so many machining professionals, hobbyists, and educators choose ACU-RITE? Keep reading to discover the top benefits of using our precision machining technologies.

What Do ACU-RITE Technologies Achieve?

ACU-RITE control and DRO systems automate manual machining. Our advanced technologies enable more accurate positioning and higher productivity while saving time and cost. The result is greater machine tool profitability.

Nearly every manual machining application can achieve next-level accuracy with ACU-RITE. Our products support professionals seeking higher production, educators inspiring the next generation, and hobbyists pursuing their passions.

ACU-RITE Controls

ACU-RITE develops entry-level controls that improve machining capabilities and accuracy in applications requiring manual and automated operation. They have broad automation features, user-friendly conversational and G-code programming, and full 3D contouring.

● MILLPWRG2 CNC Milling Control: Use it on knee and bed mills with up to three axes as a DRO, a programmable CNC control, or both.

● TURNPWR CNC Turning Control: Program manual and automated operations on turning machine tools with up to two axes plus spindle.

ACU-RITE DROs

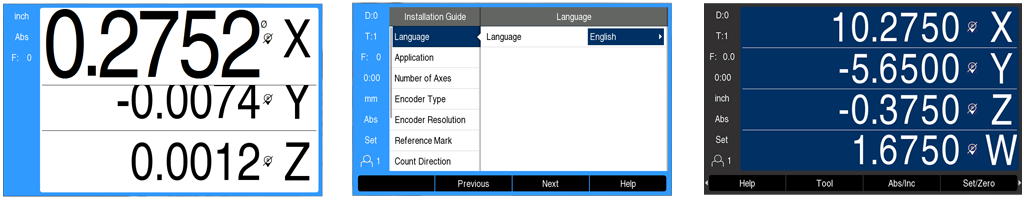

ACU-RITE DROs continuously display the true location of machine axes, eliminating the need for manual calculations. This real-time positioning feedback reduces errors significantly, improving machining accuracy. They feature pre-programmed common cycles, plus specific functions for milling and turning.

● DRO100: The most cost-effective, entry-level DRO with essential display technology.

● DRO203: Our most popular DRO, offering versatility and reliability for various machine tool applications.

● DRO203Q: Our most popular DRO, enhanced with Quadra-Chek for efficient graphic inspection and metrology applications.

● DRO300: The most complete DRO, featuring advanced programming capabilities and support for up to six axes.

● droPWR: A cutting-edge solution for transforming an iPad® into a powerful ACU-RITE DRO.

ACU-RITE Encoders

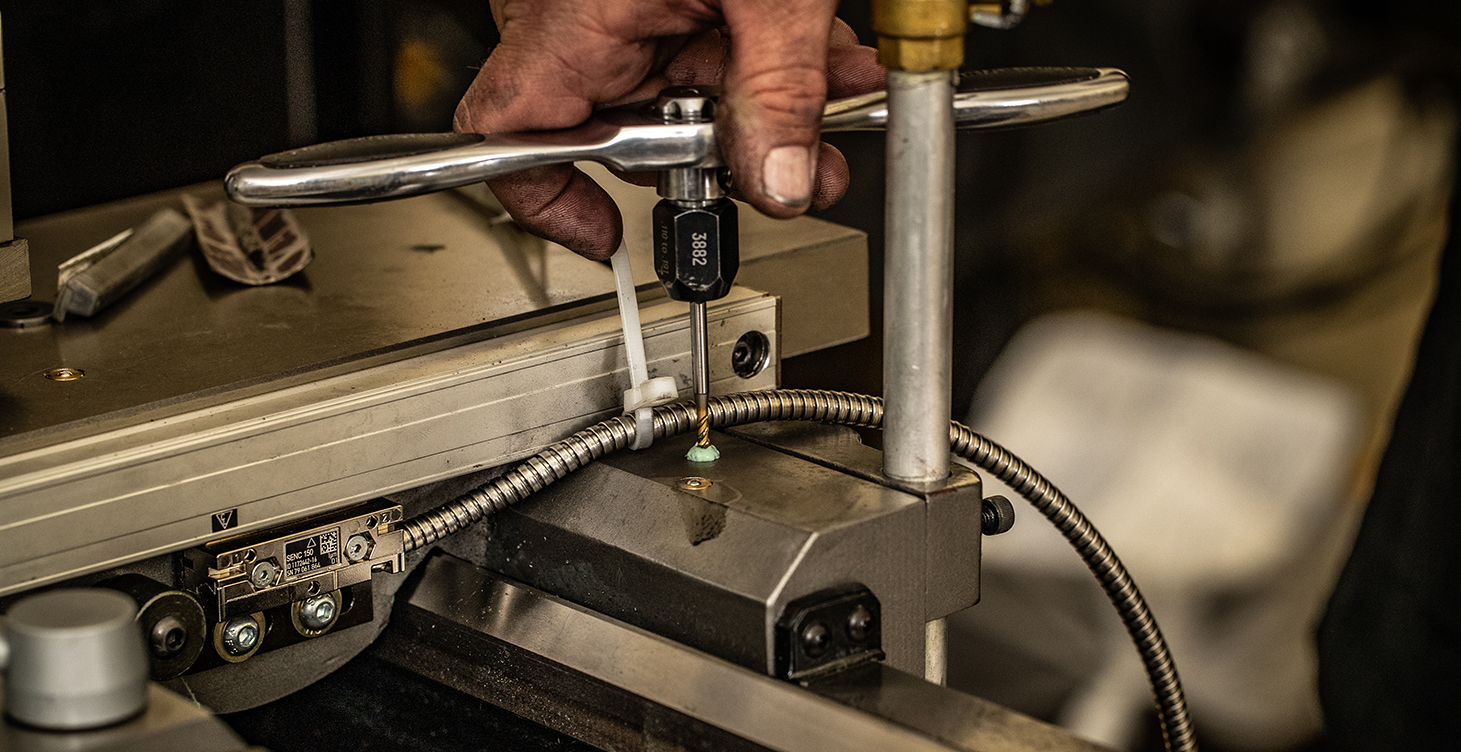

ACU-RITE controls and DROs are even more effective when paired with an ACU-RITE encoder. Our linear and inductive encoders provide repeatable, high-accuracy feedback in almost any machining application and environment.

ACU-RITE linear encoders integrate advanced optical technology that resists size, shape, and density changes due to temperature variations. As a result, they eliminate errors caused by machine wear and backlash.

● SENC 50 Linear Encoder: Highly compact dimensions maximize accuracy in tight and restricted spaces.

● SENC 150 Linear Encoder: Advanced precision technology enhances accuracy in diverse applications.

● LMF 9310 Linear Encoder: Resists virtually all contaminants while providing high-accuracy feedback for large machine tool applications.

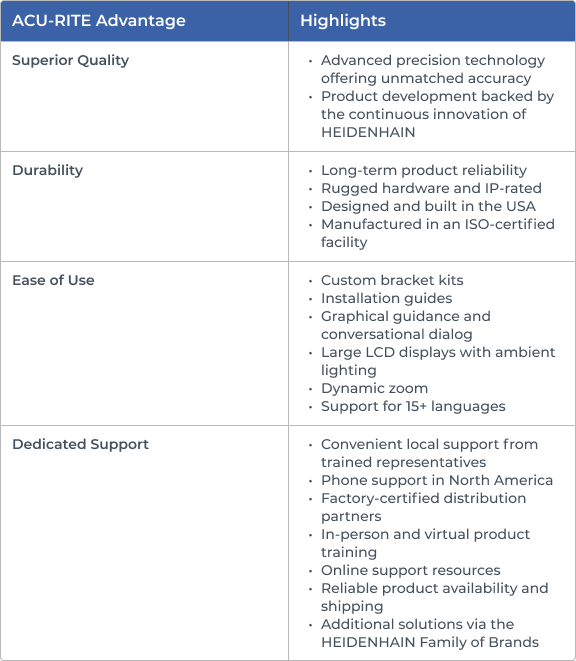

What Are the Benefits of Using ACU-RITE Technologies?

ACU-RITE products have an exceptional reputation because they improve the quality, efficiency, and profitability of manual machine tools. Our control and DRO systems integrate cutting-edge technology developed by HEIDENHAIN to machine superior workpieces. They are built to last in tough machining environments and intuitive for machinists of all skill levels to operate. They also come with dedicated customer support.

Benefit #1: Superior Quality

ACU-RITE controls and DRO systems machine superior workpieces because they are powered by the continuous innovation of HEIDENHAIN.

Founded in 1889 in Berlin, HEIDENHAIN has a century-long tradition of pioneering measurement, control, and drive system technology. ACU-RITE applies motion control innovations out of HEIDENHAIN labs in Germany to design and build its products locally, keeping its “Made in America” tradition alive.

Our joint legacy of technical ingenuity promises the most advanced precision technologies available. That is why ACU-RITE products reliably enhance machining quality and efficiency, creating better workpieces with tighter tolerances and less scrap.

Introduced in 2022, the ACU-RITE droPWR is a recent example of our ongoing product development. The droPWR is a first-of-its-kind Bluetooth-enabled DRO that transforms the iPad® into a cable-free ACU-RITE DRO. When used with the IBT400 or IBT400+ encoder, droPWR allows seamless switching between milling, turning, and grinding tasks, making it ideal for shop classes, production environments, and small shops.

Benefit #2: Durability

Investing in a durable control or DRO system maximizes manual machine tool profitability. Reliable equipment reduces downtime, repairs, and material waste, increasing production capacity and long-term cost savings.

When it comes to durability, ACU-RITE technologies stand out. Since day one, our products have been designed and built in the USA, ensuring the quality to withstand even the harshest machine shop environments. Our controls, DROs, and encoders are crafted in an ISO-certified facility, have rugged hardware, and carry an IP rating. Exceptional protection against dust, debris, and liquids means our systems can handle the demands of regular use for years.

“These DROs have proven to be of high quality and very reliable,” said Nick Sjoberg, Graduate Assistant at Southern Illinois University College of Engineering. “Even though we have ACU-RITE DROs in the shop that are older than me, they work just as well as the new ones (minus all the fancy new features).”

Benefit #3: Ease of Use

Advanced precision technology should be easy to use. That is why our control and DRO systems are intuitively designed for machinists of all skill levels. They boost efficiency through improved accuracy and time savings on setup and operation.

ACU-RITE control and DRO systems simplify manual machining operations through numerous features:

● Custom Bracket Kits: Retrofitting a manual machine is easy with our custom bracket kits, which are compatible with over 100 machine makes and models.

● Installation Guides: Our step-by-step installation guides walk the machinist through the process, making setup quick and straightforward.

● User-Friendly Interface: The user-friendly, intuitive interface features context-sensitive graphical guidance and conversational dialog.

● Large, Clear LCD Displays: Large displays automatically adjust to ambient light, ensuring clear visibility in any environment. They also feature dynamic zoom, which enlarges position values to the maximum size for improved legibility during adjustments.

● Multi-Language Support: ACU-RITE controls and DROs are intuitively designed in 15+ languages.

Choosing an ACU-RITE control or DRO system ensures every machinist can operate it easily and efficiently.

“Students can quickly go to the control for the first time, understand how the control works, what it’s supposed to do, and they can very quickly pick up and write a simple program,” said Garret Parker, Department Head of Computer-Integrated Machining at Randolph Community College.

Benefit #4: Dedicated Support

Exceptional products deserve exceptional support. We help customers leverage the full capabilities of ACU-RITE technologies to maximize machine tool profitability. Customers can receive products promptly, access convenient local support, and tap into next-level precision machining solutions from the HEIDENHAIN Family of Brands.

Reliable Product Availability

Our commitment to American manufacturing promises quality as well as reliability. Because our products are designed and built in the USA, product availability and shipping are reliable. In North America, fast-track shipping is an option. ACU-RITE customers get the technologies they need promptly, maximizing uptime.

Convenient Local Support

Customers can access product support from wherever they purchase their ACU-RITE product, ensuring convenient assistance in their local time zone.

In North America, HEIDENHAIN technical support representatives are available by phone Monday through Friday. Our vast network of factory-certified distribution partners also supports ACU-RITE products in North America.

A robust library of online support resources is available 24/7, including product manuals, tips, and instructions.

HEIDENHAIN Solutions

As part of the HEIDENHAIN Family of Brands, ACU-RITE has the scale and resources to deliver every customer the most suitable precision technology for their application needs. ACU-RITE products naturally lead users to next-level HEIDENHAIN solutions as needed.

How Fast Will You See ROI with ACU-RITE?

ACU-RITE control and DRO systems continue to be the preferred choice among machining professionals. They gain superior machining capabilities, long-term durability, intuitive design, and dedicated support—all intended to boost manual machine tool profitability.

ACU-RITE customers see a return on their investment in as little as 30 days. Try our ROI Calculator to estimate how quickly you could see a return on yours.