A digital readout (DRO) provides a simplified method of measuring and machining for operators while optimizing the accuracy and profitability of the piece of equipment. Understanding the very latest DRO options can help you enhance traditional machining operations and then some. Newer DRO platforms make it easier to accurately machine complex shapes that, at one time, were next to impossible on manual machines. DROs are also effective efficiency boosters in more applications than ever before–now they can even go mobile.

How does a DRO system work

A DRO system consists of a readout display unit and linear encoder feedback for all axes, depending on the machine tool and the length of travel. The readout continuously displays the actual location of all connected axes. With a simple keypad and software-specific functions, the operator can perform many different operations.

Linear encoders mounted on the machine contain a measurement standard and a movable scanning device or reader head. The linear encoder is installed along the full travel of the machine’s axes and the reader moves along the full length of each; electronics read the position, interpret the information and send it to the digital readout to display the precise machine movement.

Features and benefits of Acu-Rite Solutions DRO systems

Fundamentally, Acu-Rite Solutions DROs make manually operated machines more profitable, improve productivity and raise the quality of the machined workpiece. Together with the linear scales from Acu-Rite Solutions, these DROs form an economic and effective package solution for initial setup, retrofitting machine tools and more.

If you’re curious how quickly one or more DROs will pay for themselves, our ROI calculator makes the math easy, using your own shop’s numbers.

In a manual machine application, complicated shapes and patterns can be machined, but it can be a tedious and error-prone process. If a machinist wants to manually move to a location several inches or mm away, he would have to start with a known location and very carefully count the number of turns made with the hand crank handle, then stop at the correct division on the machine dial. The machine operator must be careful to keep count of how many times they crank the handle and not misinterpret the starting point. Most manual machines use standard lead screws that are not very accurate and oftentimes account for backlash present in the machine tool. When approaching the starting point of the machining operation, it is always good to approach from the same direction to eliminate the possibility of manual machine tool backlash.

With an Acu-Rite Solutions digital readout on a manual machine tool, the user can eliminate machine tool backlash as the readout will display the exact machine tool position for each axis consistently regardless of approach direction.

Acu-Rite Solutions readouts also provide common machine functions such as Tool Radius Compensation, HOLE PATTERNS, INCLINE line and ARC MILLING, Point-to-Point line milling, Tapper calculations for turning operations, and Radius Diameter calculations to name a few. Other features and benefits include:

- Since day one, nearly 60 years ago, Acu-Rite Solutions DROs have been made in America, in an ISO facility. This ensures that Acu-Rite Solutions support is available easily by phone, appointment and/or online in local time zones.

- Acu-Rite Solutions is a member of, and backed by, the HEIDENHAIN Family of Brands, a world leader in precision feedback and motion control.

- Each Acu-Rite Solutions DRO is designed for tough machine shop environments, with rugged hardware and IP-rated seals.

- Once activated, the Dynamic Zoom feature maximally enlarges the value for the axis currently being moved. The operator immediately sees which axis is currently moving and can easily read the numerical value from a greater distance. Watch Dynamic Zoom in action.

- The Axis Highlight feature makes the axis in use appear in a darker, bold font for clearer review.

- Multiple Language Support offers over 15 languages standard on each DRO.

- Sophisticated Help functions are built right into every DRO. With the press of a key, the user is taken directly to the User Manual or step-by-step installation/retrofit instruction

- When paired with an Acu-Rite Solutions scale, Position-TRAC recalls the last data after a power loss. Also, users retrofitting a DRO to their machine themselves appreciate the Installation Guide. See how Position-TRAC works

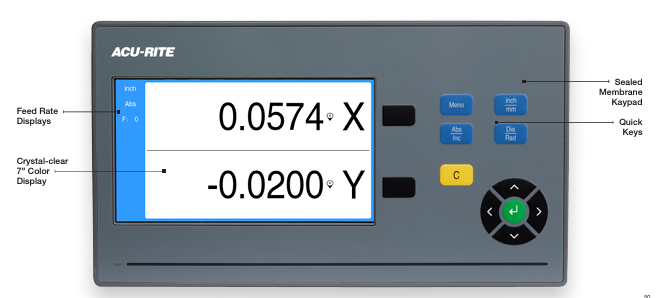

- All of today’s Acu-Rite Solutions DROs feature a standard 7-inch, color, flat-panel display that shows the actual axis position clearly

Acu-Rite Solutions DRO product overview

The product line includes everything from entry-level DROs providing measurement for a single-axis machine all the way up to advanced DROs with programming function capabilities and measurement of up to six axes. The technology has even been adapted into new options for those ready for the next step up to entry-level CNC products for both milling and turning (with MILLPWRG2 and TURNPWR controls).

DROs have commonly been used for milling (on standard and universal horizontal/vertical boring mills and jig bores), turning on lathes and surface grinders, but they are also effective on machines with an unusually high number of axes or inspection machines such as on optical comparators. Let’s run through the full DRO lineup.

DRO100

The DRO100 is a simple readout for one, two or three axes, with sturdy housing and a splash-proof membrane keyboard. The DRO100 displays position values, status information and additional useful data. The most important functions are available quickly and directly via function keys. If the DRO100 is connected to a lathe, the user can simply switch from radius to diameter display.

Besides being commonly found on milling, turning and grinding applications, this DRO is also sometimes found paired with height gages/scales in inspection rooms. This might be as part of an inspection table system for checking part tolerance offering the user a much larger readout option for example.

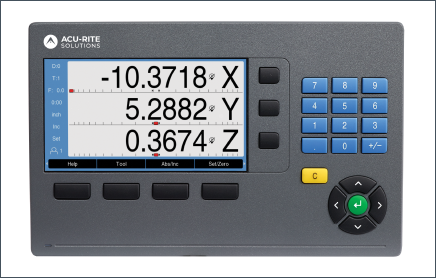

DRO203

A versatile digital readout for up to three axes, the DRO203 digital readout is designed as a sturdy, upright unit with a splash-proof, full-travel keypad for use in a workshop. Its conversational dialog guidance and distance-to-go display facilitate positioning tasks and special functions for producing hole patterns (linear patterns and circular patterns). For turning, the user can easily switch between the radius and diameter display when the position display is configured for such. On lathes with a separate top slide, the sum display feature on the 3-axis version of the DRO200 series allows for the display of the saddle and top slides together or separately.

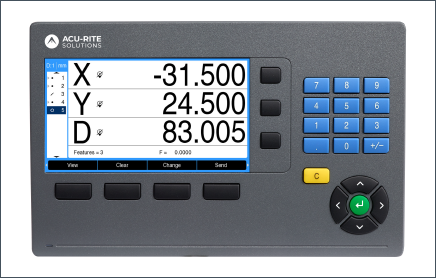

DRO203Q

Affectionately referred to as “The Q”, this model is perfect for use with optical comparators and measuring microscopes. With the help of a graphic evaluation screen and intuitive

interface, you can measure and export 2-D data quickly over a USB-C serial connection. The Q makes it possible to measure, create and construct the following feature types: point, skew, line, distance, circle and angle.

DRO300

A programmable digital readout for multiple axes, the Acu-Rite Solutions DRO300 supports all operations with intuitive interactive menus on a large color display. A separate I/O unit provides switching input/outputs for simple tasks in automation. The DRO300 allows for storage of up to eight programs, each with up to 250 working steps. Equipped with the same functions as the DRO203, the DRO300 also offers a connection for the KT 130 edge finder. This allows the user to define presets and datums with speed and precision. The DRO300 also offers programmability for small-batch production on conventional machine tools with up to four axes.

With the simple addition of the IB2X box, the DRO300 can measure up to six axes. This makes it highly effective for large machine tools. Plus, the use of an IOB610 box offers the ability to switch inputs/outputs; the user can look at the spindle speed of a milling machine or constant surface speed in a turning application.

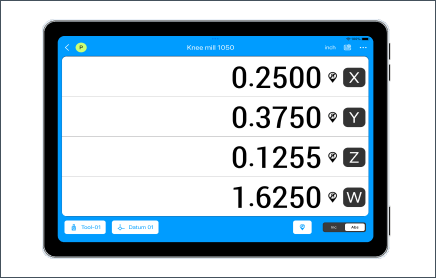

droPWR

This breakthrough technology allows users to effectively transform their tablet into a DRO. Using Bluetooth® technology, the tablet connects to the DRO system, combining an intuitive user experience with touch screen convention. Dynamic switching between applications (milling, grinding and turning), multiple user configurations and machine-to-machine switching on a single tablet makes operators and machines hyper-efficient.

How to choose the right Acu-Rite Solutions readout

While Acu-Rite Solutions DROs are versatile, you have choices, capabilities, features and options that can best match your equipment and work. The first thing to think about is the application: grinding, turning, milling, sinker EDM, inspection, etc. How many axes does the machine have? Will the DRO support one type of work or a variety? Will you need to machine more complex shapes, and save offsets or programs?

Equipped with answers to questions like these, you’ll be able to quickly identify the best Acu-Rite Solutions DRO for you. For some extra help, give our DRO Selector Tool a try.

Compatible machine brands for retrofitting

Acu-Rite Solutions DROs are exceptionally equipped for retrofitting. We’re the only readout manufacturer that offers bracket kits for specific machines and brands. This includes more than 100 different machine makes and models, from manual mills to lathes. No measuring or drilling, everything lines up flush and fast. Put simply, Acu-Rite Solutions makes hardware installation easier than any other DRO brand.

If you’re looking for some more advice on where to start or how to retrofit, read our ebook, How to Retrofit and Upgrade Legacy Machines.