Precision in Education

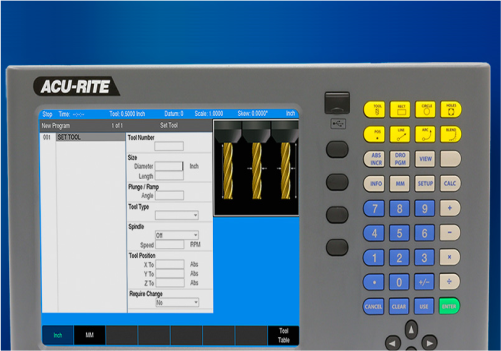

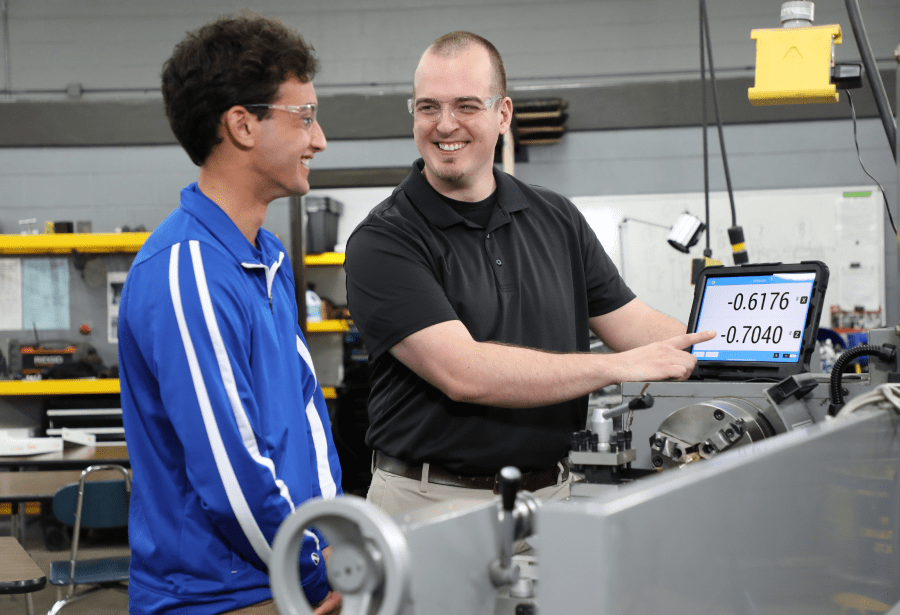

How Bates Technical College and ACU-RITE SOLUTIONS Carry Forward a Legacy of Accuracy When you step into the machine shop at Bates Technical College in Tacoma, Washington, the hum of machinery is matched only by the energy of students learning to bring precision to life. For Program Director Tim Bacon, machining education goes far beyond teaching students how to cut metal. He believes it’s equally important to prepare them to thrive in a field where accuracy, adaptability, and innovation define success. A Program Built on Purpose Bates Technical College’s machining program operates with a clear vision: to be a leading technical education program that shapes the future of machining. It does this by fostering expertise, embracing advanced technologies, and cultivating a culture of excellence and adaptability in the global manufacturing landscape. That vision is reflected every day in the lab. Students come from all walks of life — from hobbyists and career changers to aspiring entrepreneurs — united by a shared interest in learning the art and science of machining. “Our goal is to establish a solid foundation of high-demand skills that form the basis of future learning,” says Bacon. “We’ve designed our projects and activities to mirror current industry practices and standards, so our graduates are ready to step directly into professional environments.” Most of those graduates go on to find careers in aerospace, a dominant industry in the Pacific Northwest, while others find their paths in medical and construction manufacturing. Regardless of where they land, they leave Bates equipped with confidence, accuracy, and a deep understanding of how precision drives production. Empowering Learning with ACU-RITE SOLUTIONS Accuracy is at the heart of every machining operation — and at Bates, that principle is reinforced daily through the use of ACU-RITE SOLUTIONS technology. ACU-RITE SOLUTIONS, a valued member of the HEIDENHAIN family of brands, plays a key role in supporting that mission. The college’s lab is equipped with a total of 24 ACU-RITE SOLUTIONS digital readouts, including DRO102, 200, 203, and 300 models, which have transformed the way students learn and work. “Typical manual machines in industry are equipped [...]