MILLPWRG2 Halves Setup Time for Custom Glass Fabricator

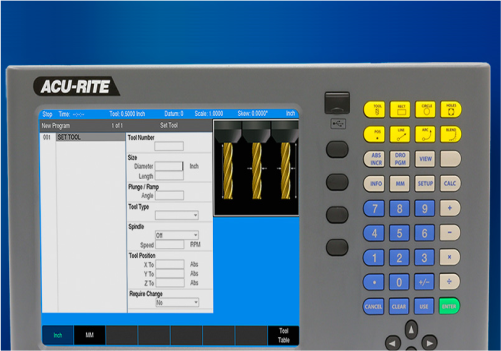

A family-owned glass fabricator in Ohio expanded its machining capabilities with the MILLPWRG2, allowing it to handle a higher volume of work and more technically demanding jobs while significantly reducing programming and setup time. Background Delivering Precision Glass Parts for Demanding Applications Machined Glass Specialists (MGS) is a family-owned custom fabricator of high-performance glass materials like fused quartz, fused silica, and borosilicate. Since its founding in 1989, MGS has continually advanced its techniques, equipment, and efficiency to create precision glass parts affordably. From its 15,000-square-foot facility in Ohio, MGS uses proprietary cutting, polishing, and inspection methods to craft one-of-a-kind glass components for industries ranging from semiconductors to medical. MGS parts are produced with the quality and reliability to perform in a variety of high-temperature, high-pressure applications. Photo Courtesy of Machined Glass Specialists Challenge Why Upgrade CNC Controls When the Old Ones Still Work? MGS wanted to keep pace with increasingly complex fabrication by modernizing its aging equipment—several milling and grinding machines and the legacy Acu-Rite Solutions MILLPWR CNC controls attached to them. Their MILLPWRs were still performing well after nearly 20 years in service, eliminating human error that could cause costly material and tool waste and lost productivity. But MGS recognized that adopting more modern CNC technology would enhance their machining capabilities and efficiency. “When it came time to buy new machines and upgrade our legacy MILLPWRs, choosing MILLPWRG2 systems was a no-brainer for us.” Jason Behm Supervisor, Machined Glass Specialists, Inc. Solution Why Was MILLPWRG2 the Right Fit for MGS’s Evolving Machining Needs? After years of success using MILLPWR CNC systems, MGS purchased a used machine with a first-generation MILLPWRG2. The team was quickly impressed by how it performed. MGS needed a CNC control that could provide precision feedback in a dusty environment while adapting to frequent program changes. The MILLPWRG2 met these needs with a high-accuracy glass scale, durable construction, intuitive programming options, and comprehensive support. The MILLPWRG2 is an entry-level CNC control for precision three-axis machining on knee and bed mills. It’s designed for [...]