The University of Pittsburgh upgrades research machine shop with MILLPWRG2

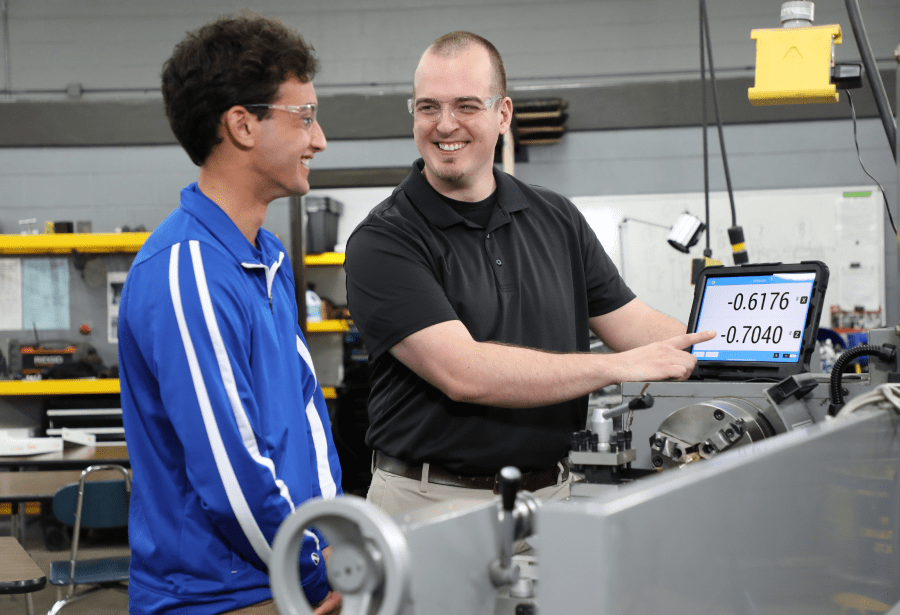

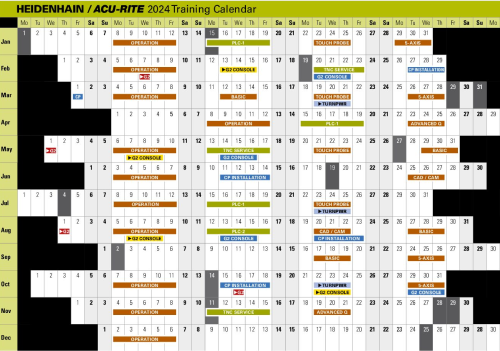

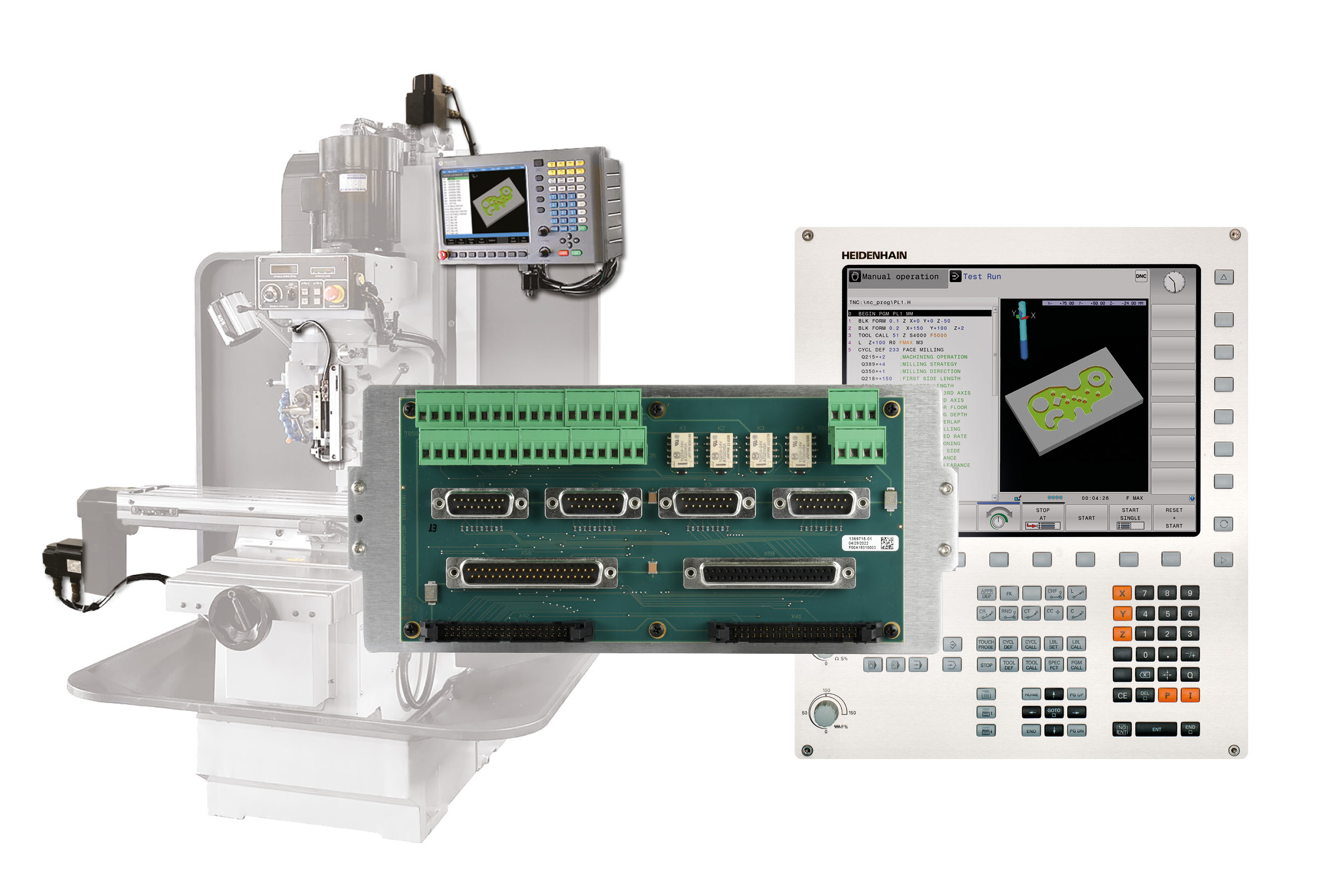

“Most people don’t realize that large universities have five or even ten machine shops throughout their campus. Some are education centers where students are trained on machinery. Other shops work for the university or even lend themselves outside of the university.” This insight was shared by our valued distribution partner, Gary Kinkela, President of Kinkade Inc. when he was discussing his recent installation of two Acu-Rite Solutions products at the University of Pittsburgh. Gary visited the University of Pittsburgh to meet with familiar faces and discuss their machine shop needs candidly. It became apparent that one of the shops faced challenges with its current equipment, particularly with a bed mill that featured an out-of-date control system. “The previous setup was old. It was aging technology. Parts could not be replaced, and the capabilities just weren’t there,” shared the shop manager, Shawn Artman. Shawn’s machine shop supports the unique machining and assembly requirements for the University’s Kenneth P. Dietrich School of Arts & Sciences. He elaborated, “We support the labs and research teams. We’ve built parts to support research for Quantum Physics and, we’ve created equipment for the Geology department to study frogs and fish underwater. Anything the school needs to be fixed or built, we do it.” After their initial shop walkthrough, Gary recommended replacing their legacy bed mill control with the MILLPWRG2 . The MILLPWRG2 is a powerful yet easy-to-operate CNC retrofit system for knee mills and bed mills. The MILLPWRG2 offers faster set-ups, shorter run times, and a major boost in productivity. hen asked why Shawn and his team selected Acu-Rite Solutions for their shop upgrade, he said, “Most of the team has worked on Acu-Rite Solutions at some point in their career. It’s a reputable brand. And when compared with the old control, Acu-Rite Solutions is just a better overall system to operate and program.” He also shared, “I am a big proponent of customer service, and the quality and support that Gary was showing us made us want to go that route.” In addition to the MILLPWRG2 upgrade at [...]